- Modular Design

- Accurate Measurement

- Engineered for Excellence

- Reliability Redefined

- Seamless Integration

- High Precision

- Plug and Play Efficiency

- No Recalibration

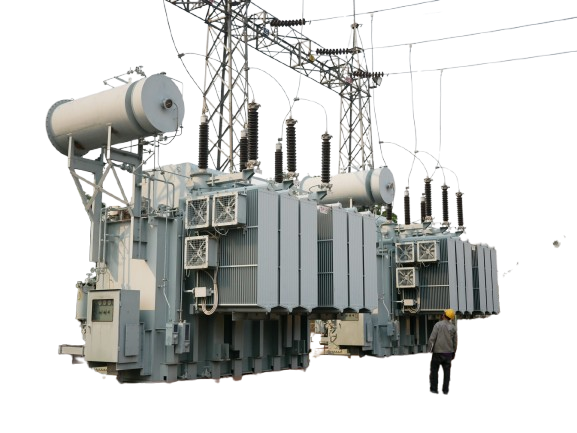

Transformer Monitoring System

At Rugged Monitoring, we understand the critical role of efficient asset management in driving operational success. Our comprehensive solutions are designed to empower businesses across global industries with actionable insights, reduce downtime, and optimize asset performance.

Why Transformer Monitoring

Reliable operation of transformers is crucial for the uninterrupted performance of power grids and asset-intensive industries. As the asset ages, its health and performance are influenced by electrical, mechanical, and thermal stressors, degrading the internal insulation system and critical components such as bushings and windings. Latent failures, such as partial discharge inception or localized thermal runaway, cause major dielectric breakdowns if not detected early on.

Traditional maintenance practices do not focus on preemptive measures, resulting in prolonged outages, safety hazards, and increased financial losses. In comparison, proactive condition monitoring allows access to continuous real-time data on critical parameters such as bushing, partial discharge, thermal hotspots, and DGA, empowering businesses with complete visibility of their assets, optimizing performance, and extending the asset lifespan.

Why Rugged Monitoring

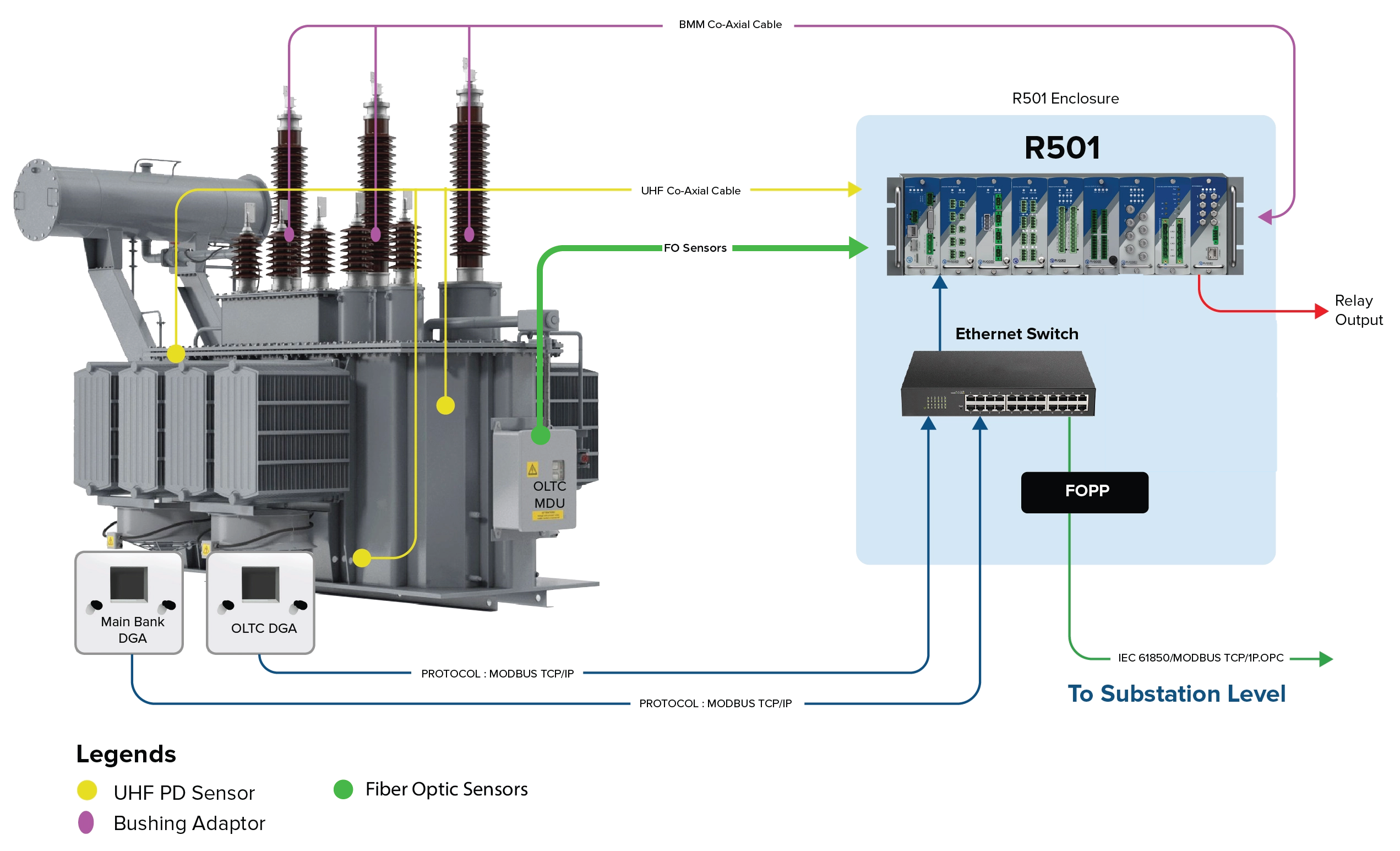

Rugged Monitoring’s Transformer Monitoring System is designed for high-precision, real-time condition monitoring of critical transformer parameters. Built around a centralized, scalable architecture, our system maintains health for individual or an entire fleet supporting EMS, DMS, industrial, and renewable applications.

Our custom engineered IoT Sensors are field deployed that seamlessly integrate with our edge devices to perform local, time-synchronized data acquisition and first-layer analytics. All the sensor outputs are aggregated into our Enterprise APM Suite, RM EYE, where advanced diagnostic algorithms, customizable alarms, and intuitive dashboards enable early fault detection. Our system also supports hybrid deployment, combining offline data with continuous online monitoring for a comprehensive transformer lifecycle condition monitoring.

Bushing Monitoring

Our solution provides continuous real-time changes for improved grid reliability and asset value.

PD Monitoring

Our highly sensitive solutions detect insulation degradation supporting proactive maintenance strategies.

OLTC Monitoring

Our solution provides real-time alerts on irregularities, optimizing performance and safety.

Temperature Monitoring

Our solutions track critical points for precise oversight into tranformer performance and health.

Hotspot Monitoring

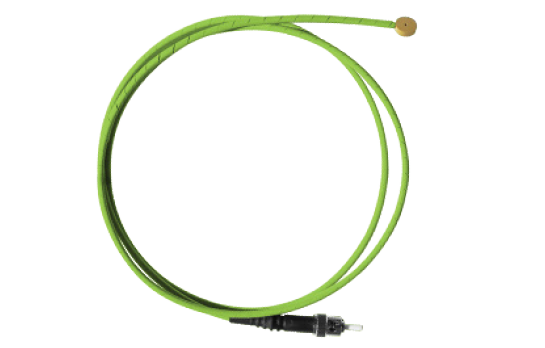

Our fiber optic solutions deliver accurate readings for the hottest spots and prevent thermal lag.

What We Monitor-

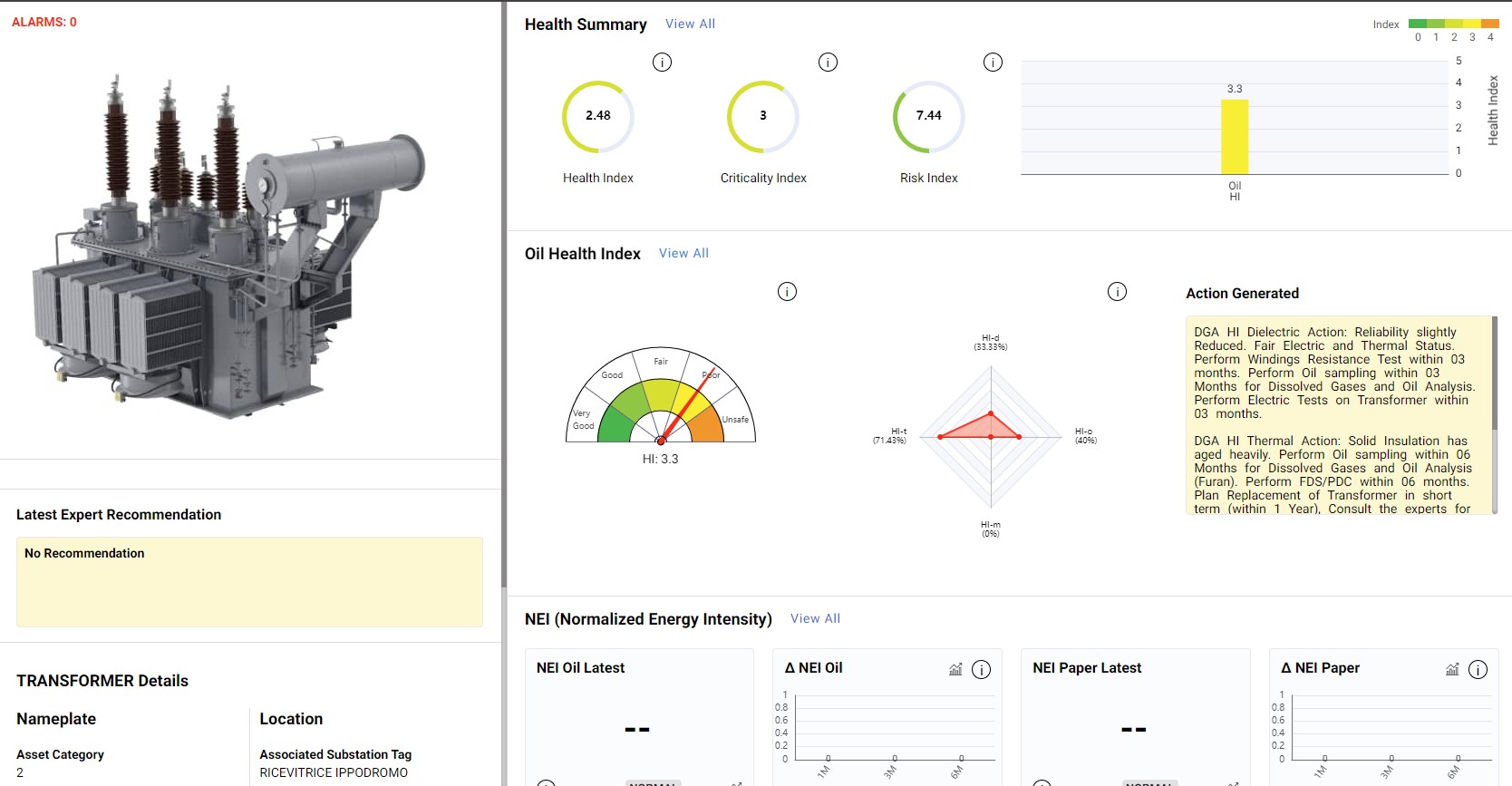

Predict, Prevent, & Perform with RM EYE

From power generation to data centers, RM EYE utilizes advanced algorithms to address issues related to critical transformer parameters such as bushing, partial discharge, and winding hotspot temperatures. Its proactive approach analyzes operational trends, detects anomalies, and predicts potential failures through informed data-driven decisions.

By fostering a more reliable infrastructure, it optimizes asset performance and contributes to maximized grid stability.

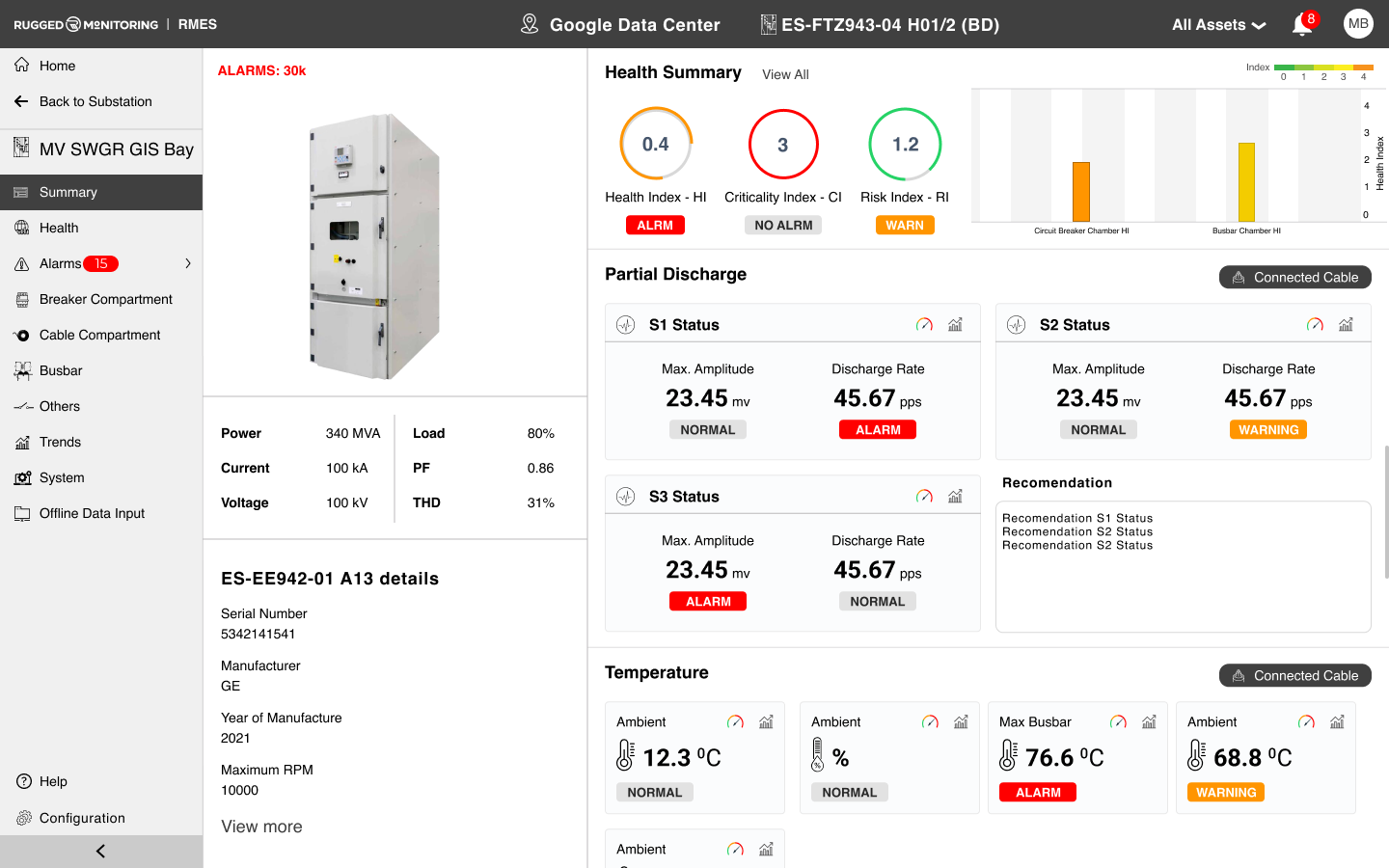

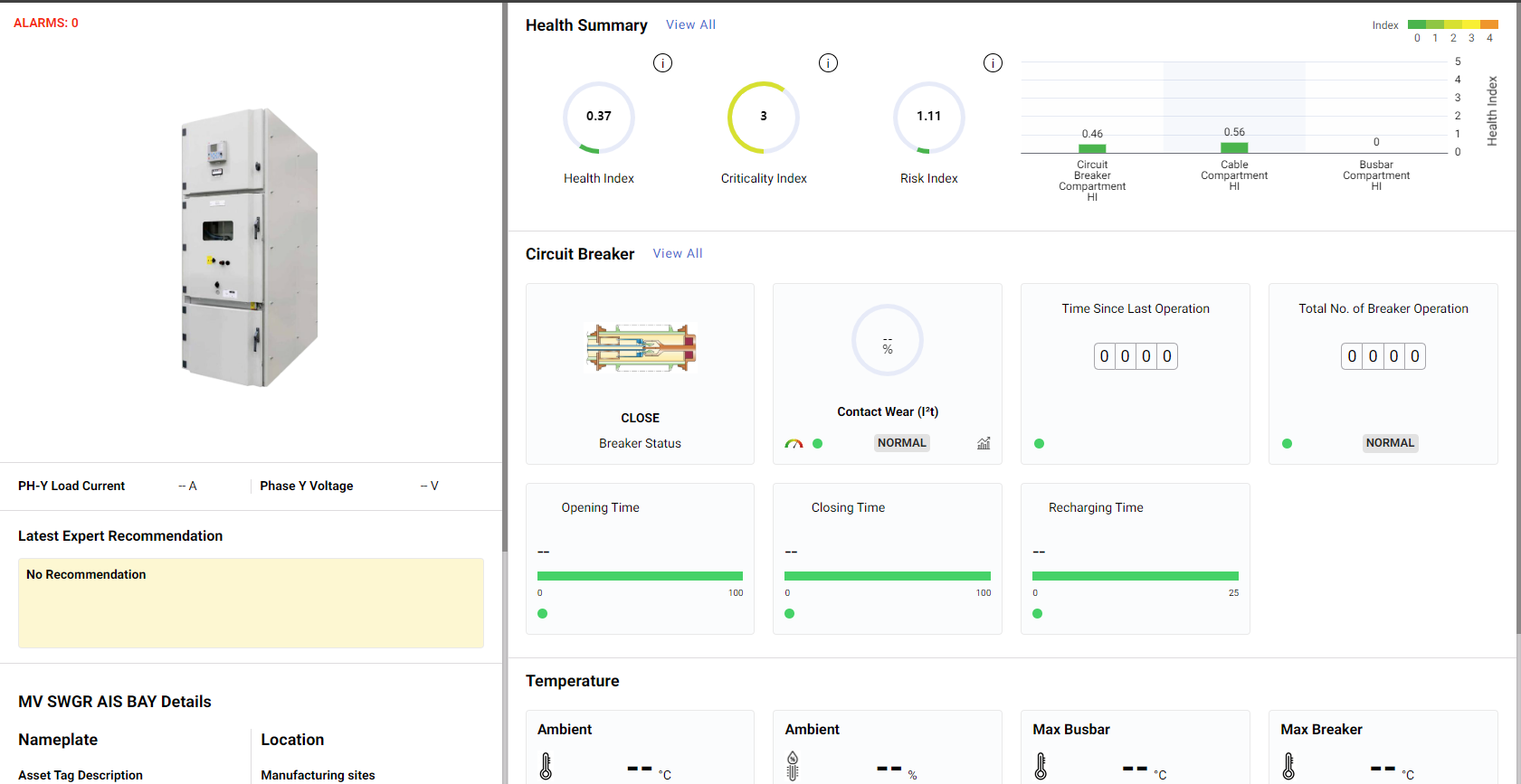

Reliable power distribution starts with a healthy switchgear system. Rugged Monitoring’s Switchgear Monitoring Solutions deliver real-time diagnostics for insulation integrity, contact wear, and internal partial discharge activity. Identifying faults before they escalate enhances safety, ensures operational continuity, and extends the lifespan of critical power distribution equipment.

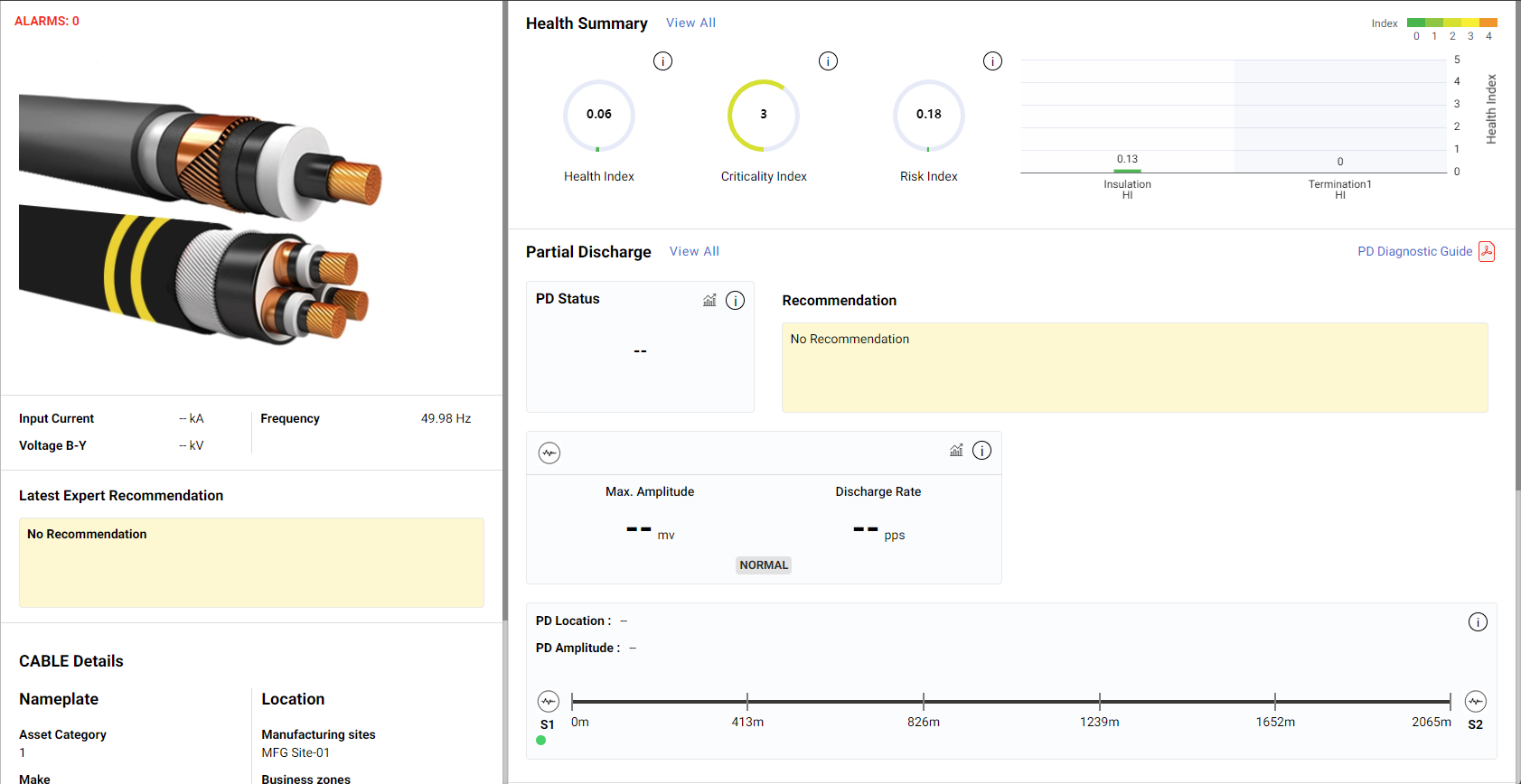

As power cables age and develop hidden defects, the risk of catastrophic failures increases. Rugged Monitoring’s Power Cable Monitoring System effectively detects real-time thermal stress, partial discharge activity, and insulation degradation. By identifying weaknesses before they result in outages, it not only boosts grid stability but also cuts down on maintenance costs.

Circuit breakers are the first line of defense against electrical faults. Rugged Monitoring’s Circuit Breaker Monitoring System offers real-time insights into breaker timing, contact resistance, and insulation health, enabling proactive fault detection.

It further prevents unexpected trips, enhancing power system resilience and ensuring reliable protection.

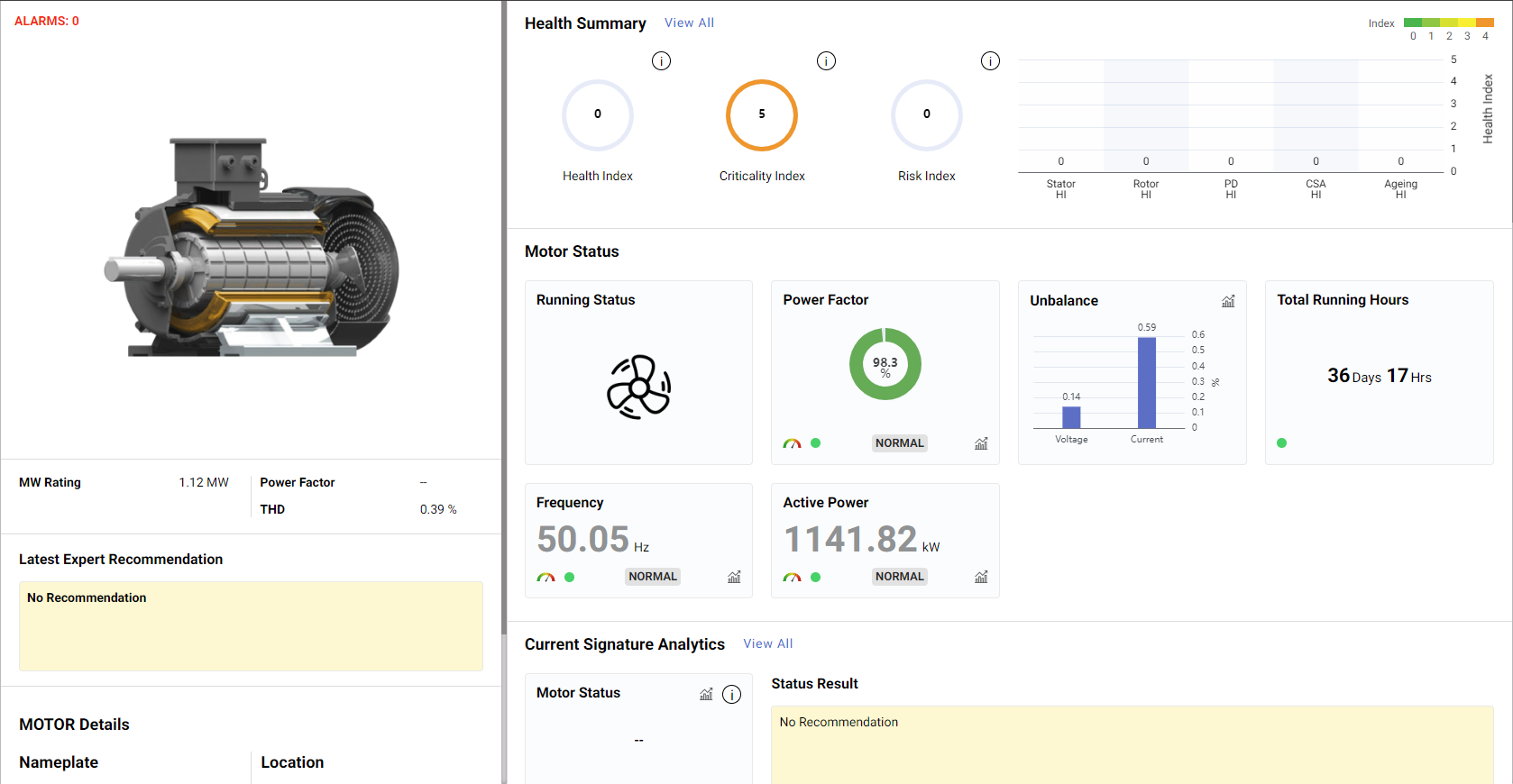

Unplanned failures in rotating machines can halt entire operations. Rugged Monitoring’s Rotating Machine Monitoring System continuously tracks temperature fluctuations, vibration anomalies, and electrical stress.

Designed for motors, turbines, and generators, it enables predictive maintenance, reducing mechanical wear and improving overall equipment reliability.

What We Monitor-

Our fiber optic solutions deliver accurate readings for the hottest spots and prevent thermal lag.

Our solutions track critical points for precise oversight into tranformer performance and health.

Our solution provides continuous real-time changes for improved grid reliability and asset value.

Our highly sensitive solutions detect insulation degradation supporting proactive maintenance strategies.

Our solution provides real-time alerts on irregularities, optimizing performance and safety.

Our solutions enable proactive adjustments for reliable transformer operation and extended lifespan.

Our DGA solution provides real-time analysis for targeted monitoring and reducing unexpected failures.

Invest in Efficiency & Sustainability

Resistant to electromagnetic interference, ensuring highly accurate condition monitoring even in extreme environments.

Comprehensive, scalable, and precision-driven for monitoring critical parameters and advancing predictive maintenance.

Designed with intelligence to drive innovation and enhance AI-powered electrical asset condition monitoring.

Head Office And Manufacturing Unit

1415 Frank-Carrel, Suite 230, Quebec, QC – G1N 4N7.

At the helm of electrical asset condition monitoring, we champion ‘Quality First’. Our ISO 9001-2015 certification underscores our commitment to excellence. Through innovation, passion, and persistent integrity, we lead with creativity and growth. We are not just leaders; We are the trendsetters, dedicated to delivering the best products and service at every step of the way.