Why Partial Discharge Monitoring in Power Cables

Partial discharge in power cables occurs at localized spots within the insulation from stress caused by impurities in its material. These discharges can result in dielectric losses, chemical reactions, and noise, all of which contribute to the degradation of the insulation over time and ultimately compromise its overall integrity. Additionally, partial discharges produce heat, leading to localized thermal stress points along the cable’s length. In severe instances, they can cause arcing and flashovers, resulting in equipment damage, fires, and explosions. Collectively, these issues stemming from partial discharges can lead to significant electrical asset failures, reducing the efficiency of the grid. While traditional time-based maintenance contributes to identifying these faults, it’s often too slow and serves as a reactive strategy.

In contrast, proactive maintenance involves real-time monitoring of partial discharges, allowing for early identification of potential failures before they occur. This approach helps to minimize unplanned downtimes, reduce maintenance costs, and mitigate safety hazards.

Why Rugged Monitoring-

Rugged Monitoring’s Partial discharge monitoring in power cables offers fully autonomous, high-precision IoT sensors, edge devices, and software for power cables. Our comprehensive system assesses the insulation condition at critical locations such as cable joints and terminations. By deploying a combination of High-Frequency Current Transformers (HFCT), Transient Earth Voltage (TEV) sensors, and Ultra High Frequency (UHF) sensors, our PD system enhances diagnostic accuracy and helps confirm whether the PD is internal to the cable or caused by external noise. These multiple sensing modalities ensure comprehensive coverage and improve the confidence of PD detection. Moreover, our solutions hold the ability to seperate PD signals from background noise, a common challenge in high-voltage environments.

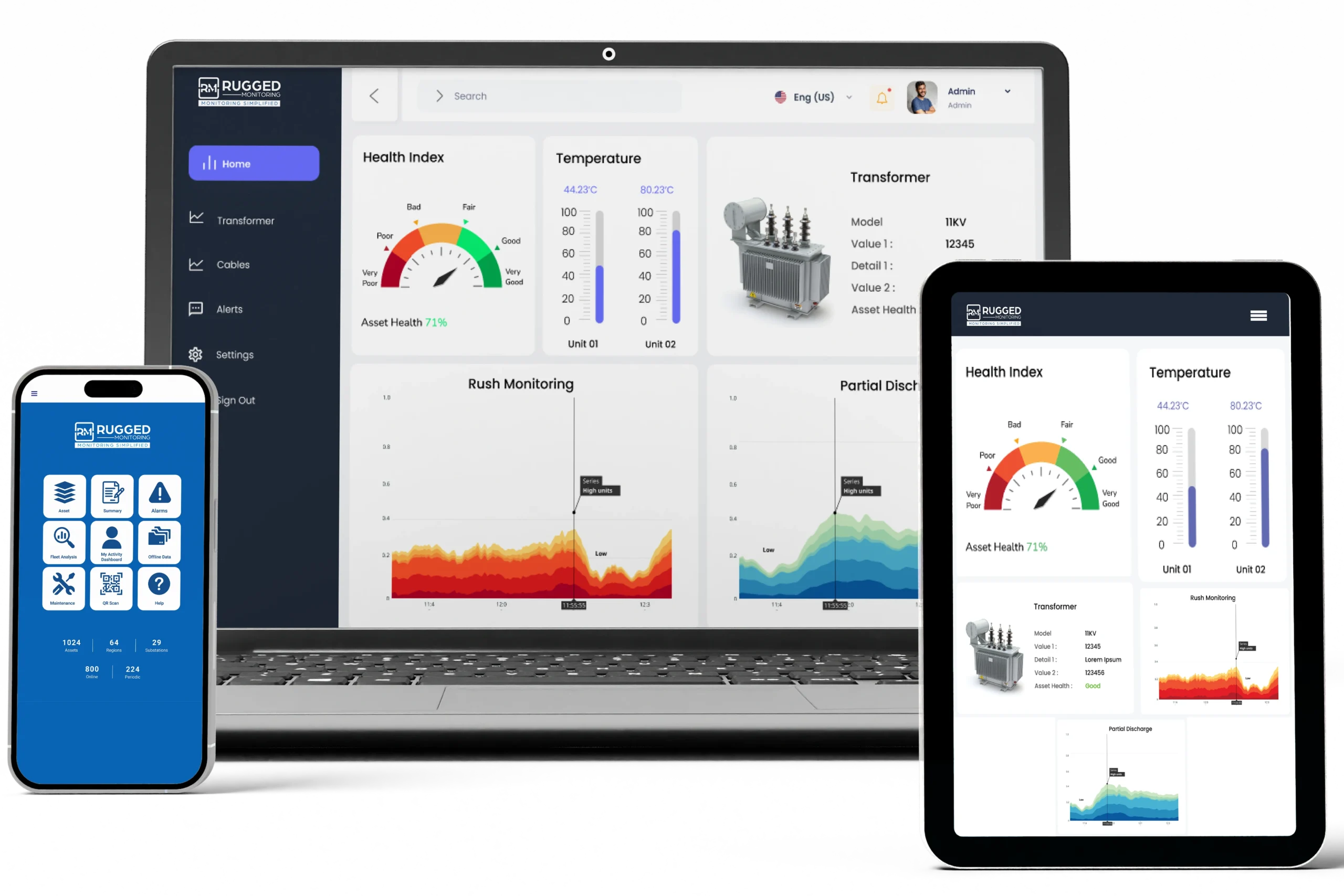

Our PD system can be implemented using single-phase or multi-phase detector configurations based on technical or commercial requirements of the application. Our solutions provide real-time insights across HV, MV, and LV assets under both AC and DC power conditions. These insights support informed decision making for asset maintenance through customizable alarms and intuitive dashboards empowering businesses to mitigate risks, minimizing downtime, and extending asset lifespan.

Invest in Efficiency & Sustainability

Rugged and reliable IoT sensors for precise early detection of insualtion degradations.

Continuous and scalable partial discharge monitoring with smart edge devices.

Advanced health and performance indices for real-time data-driven decisions of PD.

What We Monitor-