The wind farm is one of the most prominent green energy solutions. It’s a leading technology in the rapid growth of renewable energy. Wind turbines operate on a fundamental principle: they harness the kinetic energy of wind as a primary source of energy, converting it into electrical energy. This clean energy leads to a reduction in the amount of greenhouse gases in the atmosphere and provides a reliable, efficient, and sustainable energy supply worldwide.

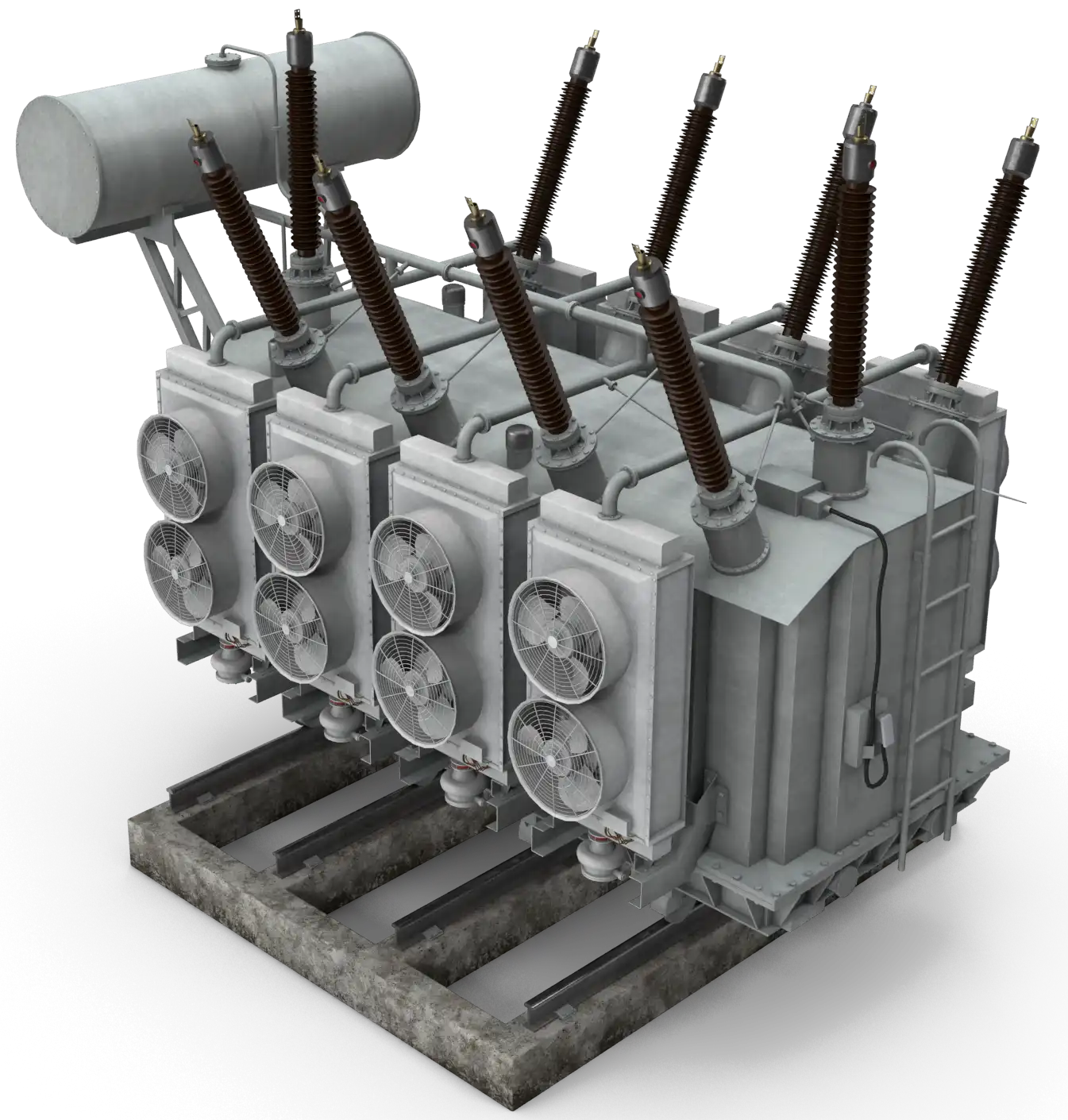

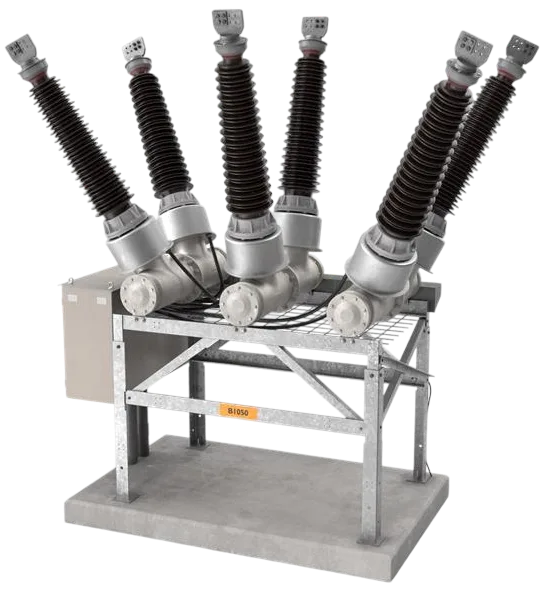

Wind farms operate as centralized or distributed energy systems, consisting of multiple wind turbines connected through a complex electrical network that includes transformers, switchgear, cables, and control systems. The performance and longevity of wind farms are directly tied to the health of these electrical components. As turbines grow in capacity and remote installations become the norm, real-time condition monitoring and predictive maintenance become critical to maintaining efficiency and grid stability.