Why Hotspot Monitoring in Power Cables

Hotspots in power cables are often caused by a combination of electrical, mechanical, and thermal stressors. These can arise from factors like loose connections, electrical overloads, or insulation degradation. Such stressors indicate abnormal conditions that can lead to electrical fires or power outages, and they accelerate the aging of cable materials, resulting in premature failures. If left unaddressed, these hotspots may cause the cable insulation to break down, further diminishing its dielectric strength and increasing vulnerability to faults. Traditional hotspot monitoring frequently fails to detect minor hotspots or other contributing issues, leading to unexpected outages that can result in significantly higher costs.

By implementing proactive maintenance strategies, continuous monitoring can be ensured, even for the most minor temperature hotspots, enhancing cable safety, extending lifespan, and boosting its reliability.

Why Rugged Monitoring-

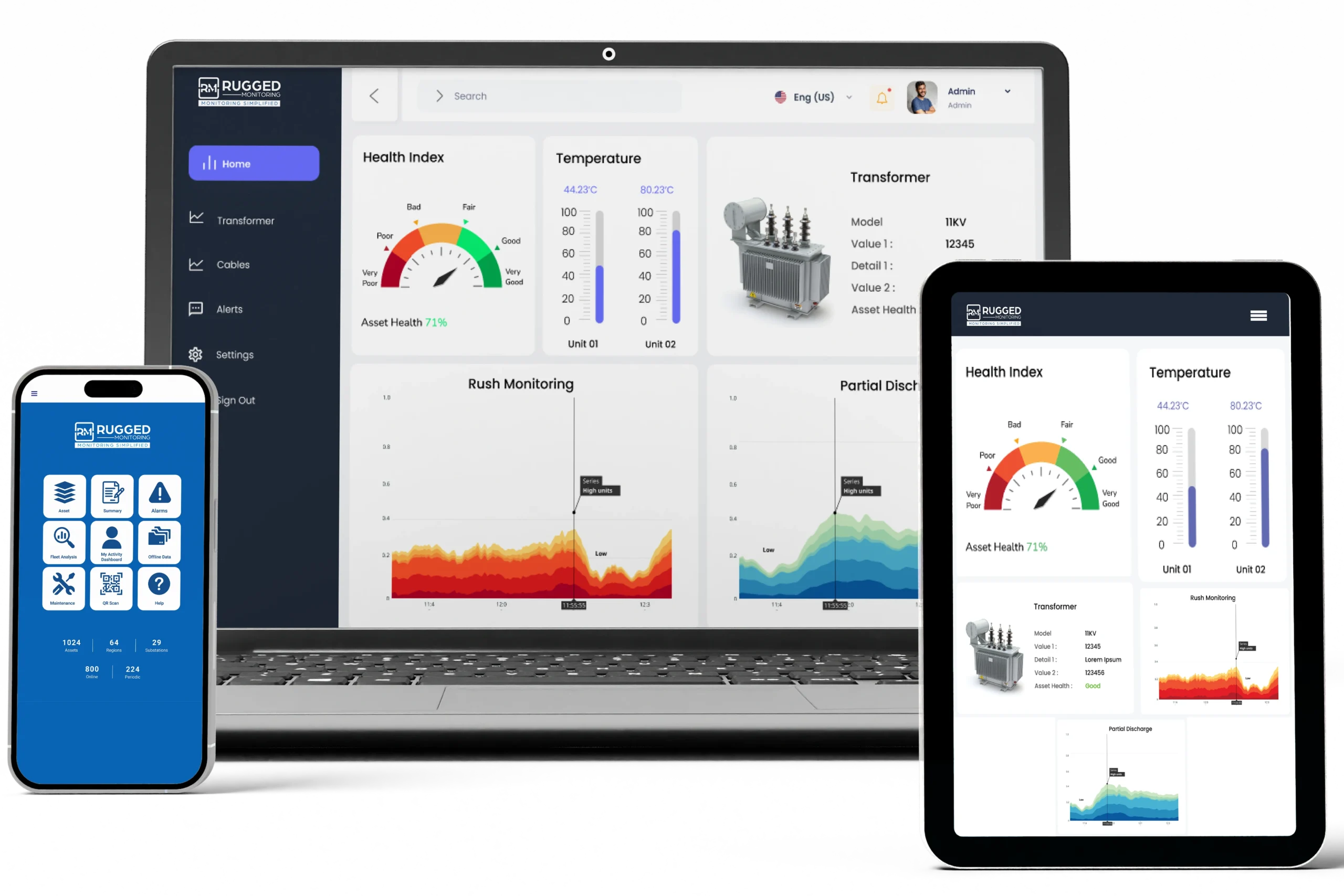

Rugged Monitoring’s solutions specialize in precision-driven, real-time hotspot monitoring in power cables that enhance safety, reliability, and efficiency of power cable systems. Our fiber optic sensing technology, including IoT sensors, edge-devices, and software continuously track hotspots along the cable surfaces allowing for immediate detection of anomalies before they result in catastrophic failures. Our system employs highly-sensitive IoT sensors that detect factors such as overloads and insulation problems that might indicate thermal build-up. Built to endure harsh environments, our solutions utilize industrial-grade components that provide immunity to electromagnetic interferences even in high voltage conditions.

Additionaly, our solutions allow seamless integration with SCADA, DCS, and APM platforms, ensuring minimal disruption during deployment. With features such as customizable alarms, intuitive dashboards, and data-driven analytics, our complete system enhances safety and compliance, helping to mitigate fire risks and extend asset lifespan.

Invest in Efficiency & Sustainability

Resistant to electromagnetic interference, enabling accurate temperature monitoring across cable joints and surfaces in harsh environments.

Comprehensive, scalable, and precision-driven for continuous thermal tracking and early detection of overheating conditions.

AI-powered platform that transforms real-time temperature data into predictive analytics to reduce failures and extend cable life.

What We Monitor-