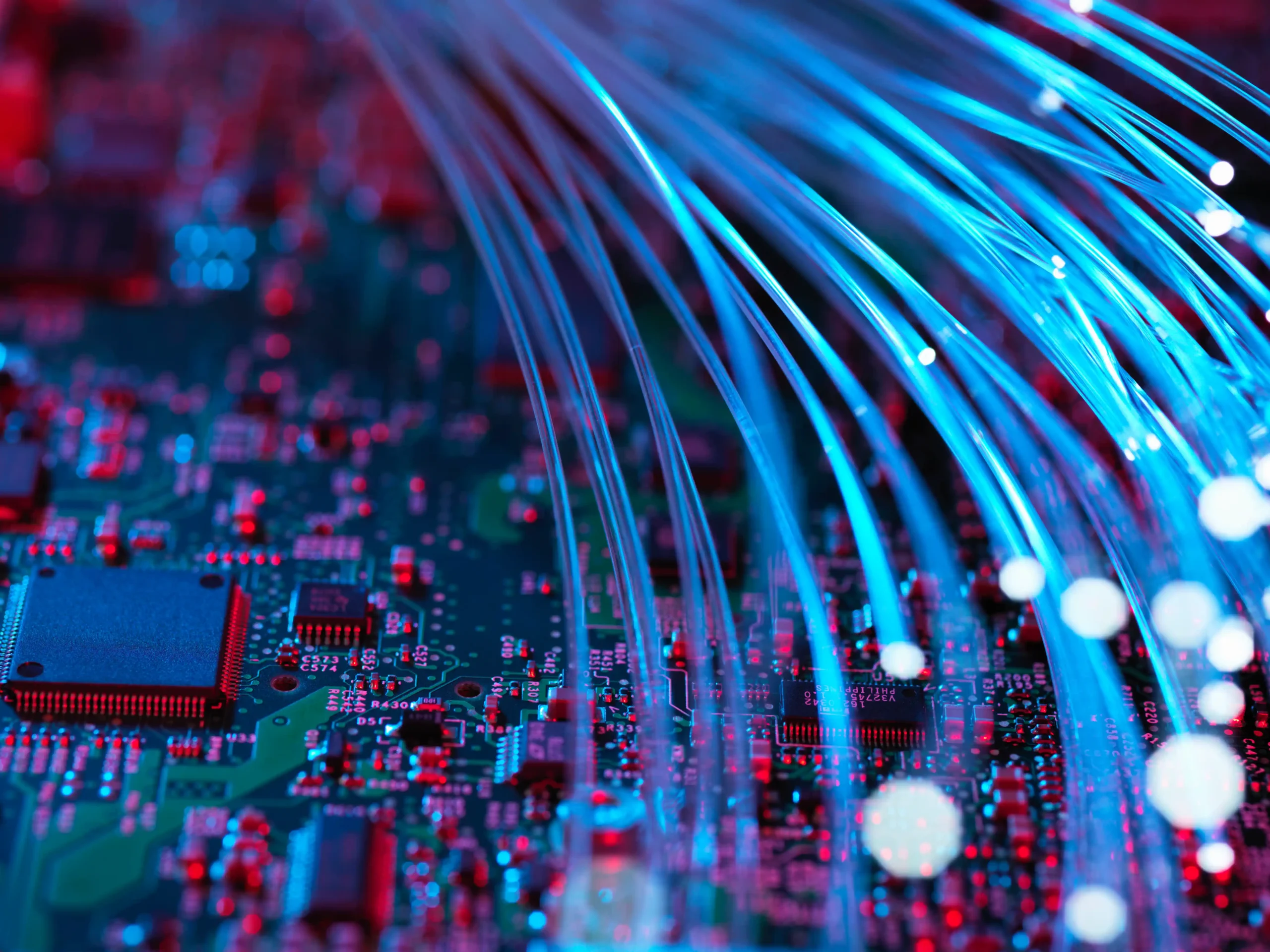

PWM is a fundamental component of modern electronic control systems, enabling precise regulation of voltage and current across a wide range of industrial applications. By generating controlled energy pulses, PWM ensures efficient control of speed, torque, and power in motors, actuators, and lighting. This technology is widely used in automation systems, electric vehicles, robotics, and embedded electronics to enhance performance and energy efficiency, even under demanding conditions.

Industries such as renewable energy, manufacturing, and consumer electronics rely on PWM not only for accurate power control but also for reducing energy loss and improving heat management. Its dynamic, low-loss switching makes it a key enabler of reliable, high-efficiency operation.