Why Hotspot Monitoring in Circuit Breakers

Overheating in circuit breakers, particularly in the primary circuit is a key factor in accelerating insulation degradation and decreasing equipment life. Early fault detection through hotspot monitoring prevents breakdown of insulation and system failure. Such hotspot occurrences are usually due to concentrated resistance and poor heat dissipation in critical components. Typical causes are loose joints resulting from vibration, bad connections from short circuit or aged clamps, mechanical contact damage of sliding contacts, and elevated resistance from corrosion or oxidation caused by moisture or contamination. Also, possible failure precursors such as oil or SF₆ leakage must be carefully tracked through their thermal signatures.

Continuous temperature monitoring tracks real-time thermal data to help diagnose the root causes of failure. With proactive maintenance, asset managers can analyze trends, receive alarm alerts, and monitor systems remotely, offering early warnings to prevent unplanned outages and costly equipment failures.

Why Rugged Monitoring-

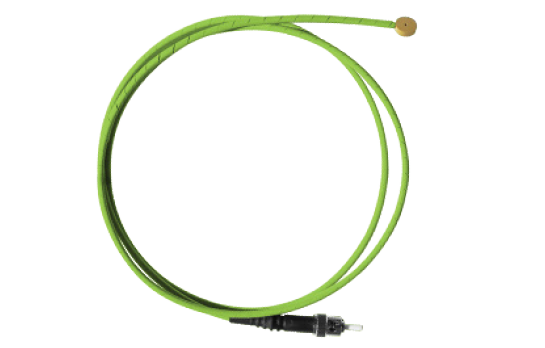

Rugged Monitoring’s Hotspot Monitoring in Circuit Breakers offers a complete solution for thermal anomaly detection in circuit breakers before they cause failures with intelligent IoT sensors, edge devices and software. Our advanced fiber optic technology tracks key areas where loose connections, contact deterioration and oil or SF6 leakage can generate severe thermal buildup.These sensors are non-intrusive, highly accurate, and immune to electromagnetic interference, making them ideal for high-voltage environments. Also, they requires no recalibration and are fully compatible with retrofit and new installations.

Our hotspot monitoring system monitors real time temperature data which combines with remote monitoring.It provides early warnings, user-definable alarms, customized dashboards and advanced analytics to identify high-risk areas that need attention. This facilitates proactive maintenance, minimizes false alarms, and reduces unplanned outages.By enhancing thermal visibility and facilitating planned action, Rugged Monitoring supports extended circuit breaker life, reduces downtime, and enables a safer, more predictive maintenance culture. This approach promotes uninterrupted and consistent operation throughout the electrical system.

Invest in Efficiency & Sustainability

Non-intrusive and EMI-resistant, enabling precise real-time detection of hotspots caused by contact wear or loose connections in circuit breakers.

High-precision and scalable, processing localized temperature data to identify thermal anomalies and support proactive maintenance strategies.

AI-powered platform delivering real-time thermal insights, smart alerts, and trend analytics to reduce outages and extend breaker reliability.

What We Monitor-

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.