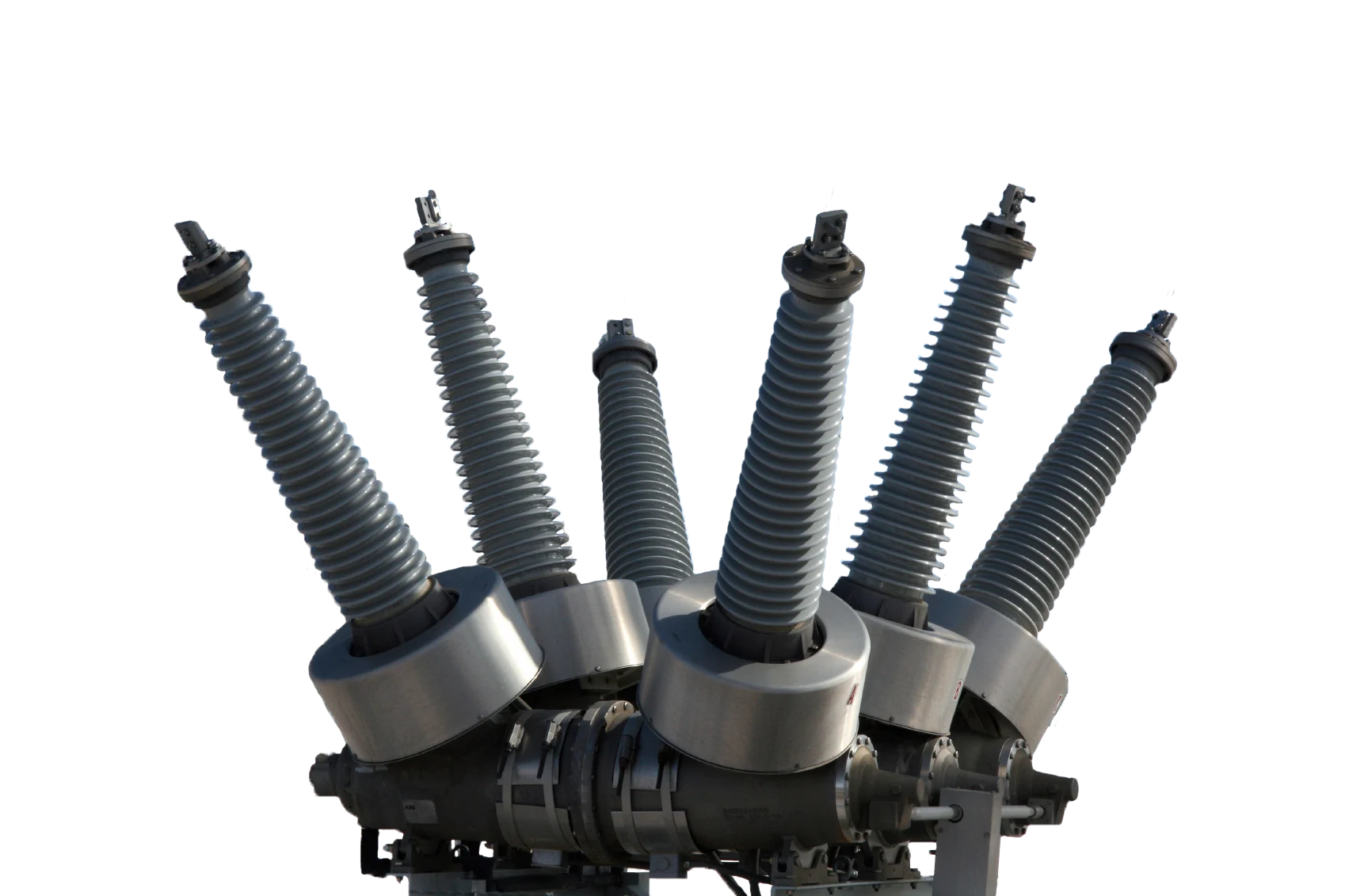

Why Bus Bar Monitoring in Circuit Breakers

Bus bar in circuit breakers operate as a conductor, interconnecting multiple electrical connections. They are responsible for providing reliable gateway for current flow, connecting incoming power sources to outgoing feeders. Thus, when a bus bar fails in a circuit breaker, the entire system is affected. While aging and other environmental factors such as moisture or arcing affect the health of this critical equipment, a majority of the failures occur due to overheating. Traditional maintenance responds to warnings periodically compromising the reliability of the asset.

Proactive maintenance address critical bus bar issues in real-time, identifying risks before a total asset shutdown. With automated data collection, O&M processes are simplified, minimizing costs of maintenance and improving asset reliability.

Traditional maintenance of switchgear fails to capture these early signs of failure, resulting in long-term power outages and asset damage. With proactive condition monitoring of switchgear, these unreliability challenges are addressed in real time, ensuring low-cost maintenance, improved operations, and maximized asset efficiency.

Why Rugged Monitoring-

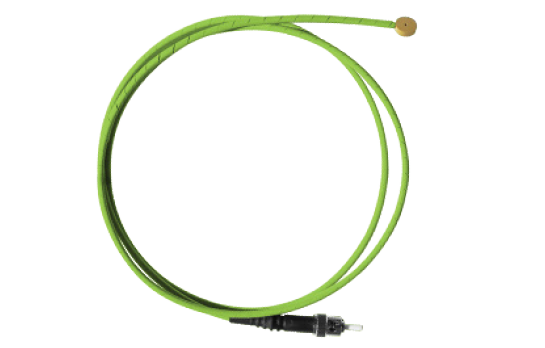

Rugged Monitoring’s bus bar monitoring in circuit breakers is capable of detecting critical bus bar parameters such as temperature, insulation degradation, and hotspots in real-time aligning with proactive maintenance strategies. Our intelligent IoT sensors and edge devices, employ non-intrusive, plug-and-play installation for both new and retrofit equipment. By ensuring uncompromising immunity to electromagnetic interferences, our solutions deliver continuous monitoring even in extreme environments. With a standard deviation of just +/-0.2 °C, our fiber optic sensing technology performs repeatable measurements without influencing the accuracy of the results. Our solutions are also non-conductive and dielectric, making them suitable for high-voltage environments.

Our software seamlessly integrates with our condition monitoring solutions ensuring remote cloud-based monitoring. Advanced machine learning algorithms are applied to the aggrevated data in a centralized data-base to detect abnormal temperature patterns in real-time. Thereby offering features like customizable alarms, thresholds, and dashboards that eliminate the risks of asset downtime and improved load management.

Invest in Efficiency & Sustainability

EMI-resistant and non-intrusive, enabling accurate, real-time monitoring of bus bar temperature and insulation health.

High-precision and scalable, processing local temperature data for early hotspot detection and predictive maintenance.

AI-powered platform delivering real-time insights, automated alerts, and load analysis to prevent downtime and optimize breaker performance.

What We Monitor-

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.