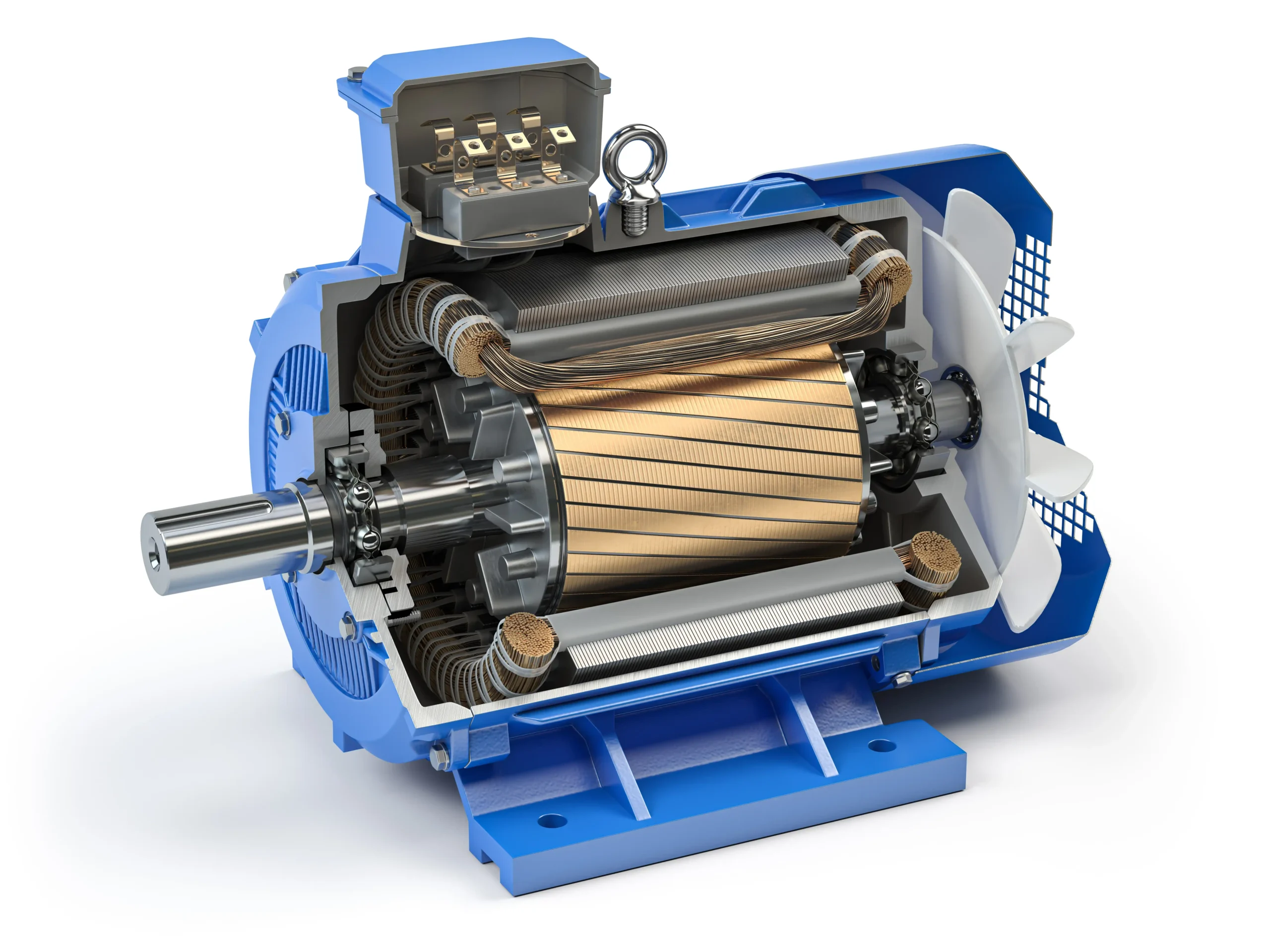

Why Temperature Monitoring in Rotating Machines

Thermal wear is the most likely cause of failures in rotating machines leading to complete breakdown of the asset. A subset of this thermal impact is, temperature fluctuations which occur with energy losses during asset operation, that gets converted to heat. These faults can either happen at a single point of the asset or multiple locations causing a full-blown outage, reducing the reliability of the machine and increasing repair costs.

Proactive temperature monitoring in rotating machines identifies these fluctuations at an early stage minimizing unexpected failures and significantly improving the businesses operational efficiency. With real-time data-driven indicators, O&M engineers can also estimate a lower valuation on reaccuring maintenance, maximizing their ROI.

Why Rugged Monitoring-

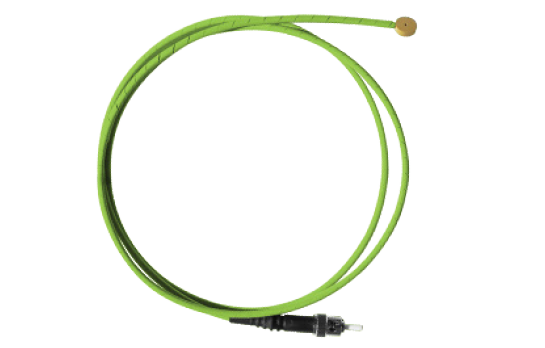

Rugged Monitoring’s fiber optic monitoring solutions including IoT sensors, edge devices, and software provide precise temperature variations by continuously monitoring dynamic behaviour of the asset. Our solutions have strong anti-interface properties that ensure reliability even in extreme conditions. They yield a stream of continuous data with high-sensitivity to provide early indicators of temperature breakdowns. Our system offers both GaAs (Gallium Arsenide) and Fluroscense technology to ensure high accuracy and a faster response time. With solutions available for both continuous and portable monitoring, our hotspot monitoring system is tailored to meet various industrial needs.

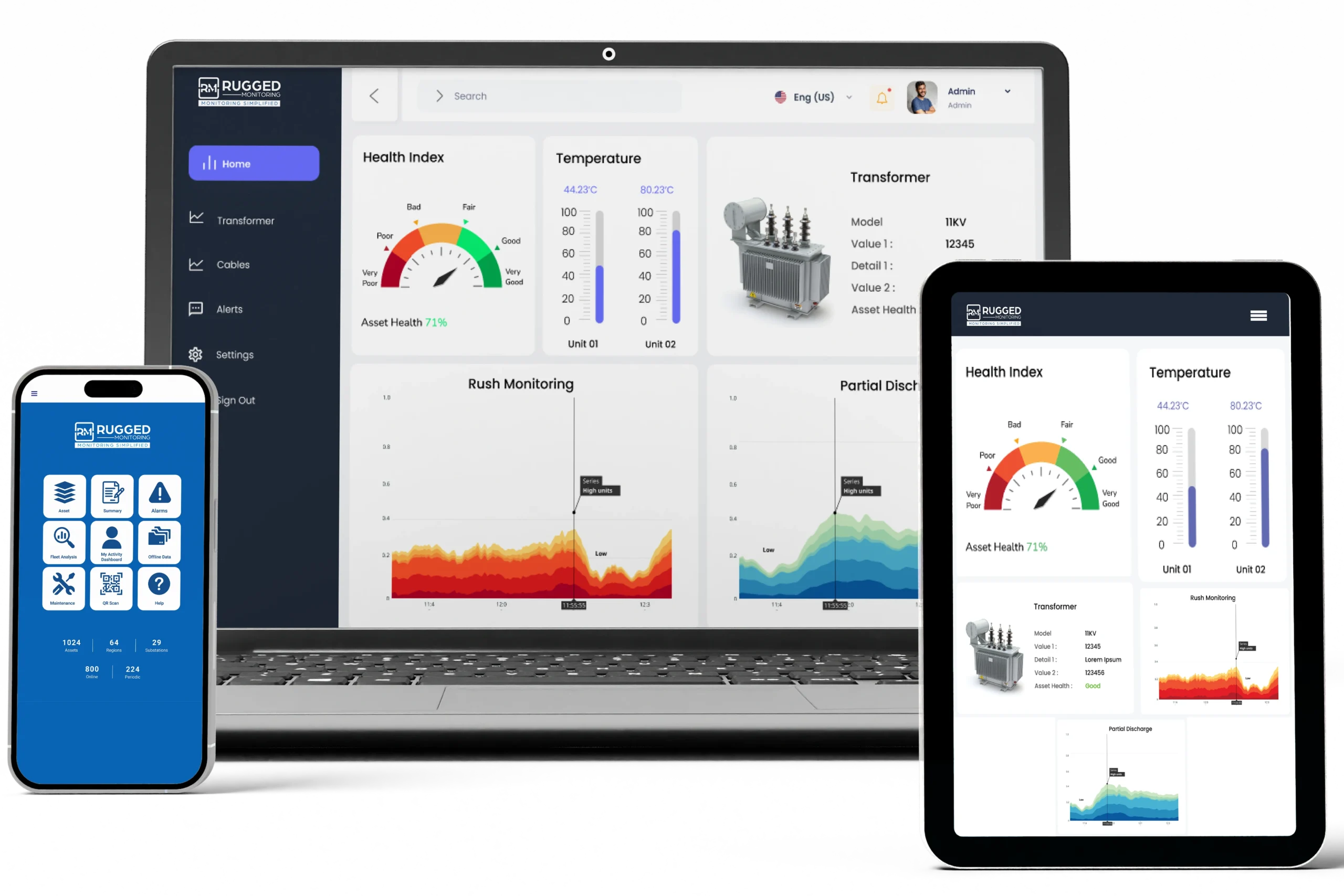

Beyond cloud-based monitoring, our solutions use advanced machine learning algorithms on the aggregated data to identify intricate patterns for asset maintenance and performance metrics. Asset managers and SME’s can also, utilize these analytics to customize alarms and dashboards, ensuring continuous asset availability, optimized efficiency, and increased cost savings.

Invest in Efficiency & Sustainability

High-sensitivity fiber optic sensors with strong EMI resistance provide accurate temperature data in extreme conditions.

Precision-driven and scalable, enabling real-time analysis of temperature behavior for early failure detection.

AI-powered software that analyzes temperature trends, customizes alerts, and drives predictive maintenance for continuous asset reliability.

What We Monitor-