Switchgear Monitoring System

Why Switchgear Monitoring

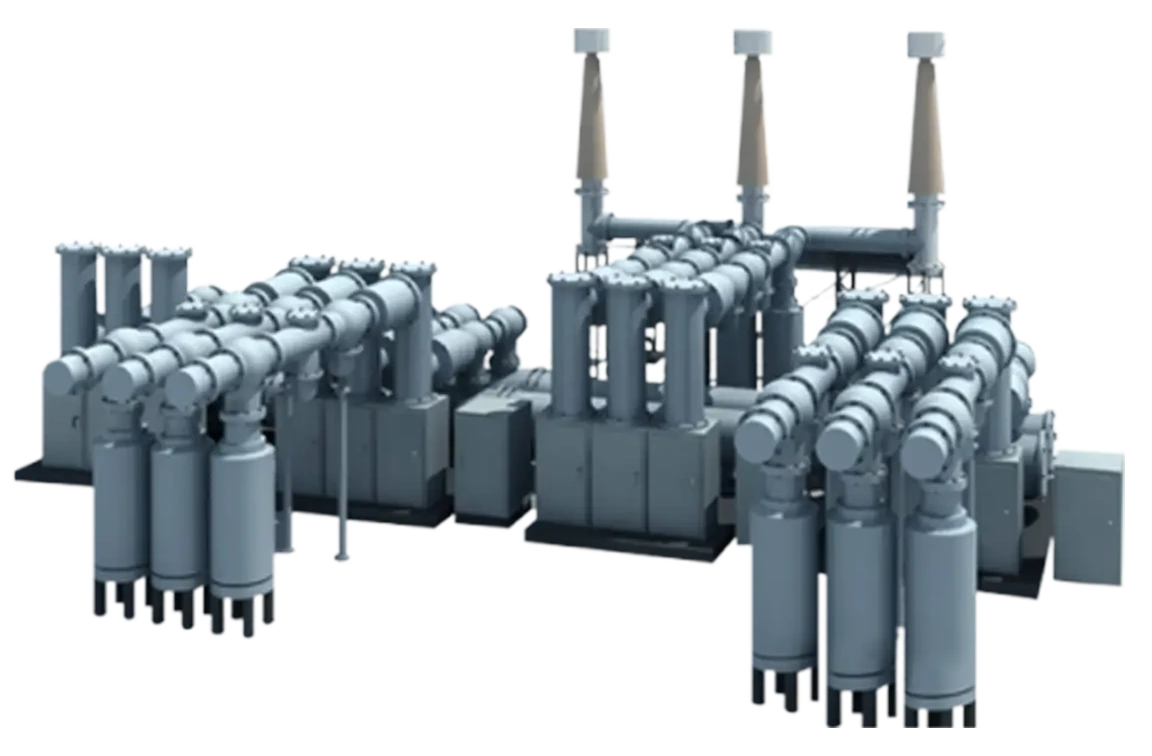

Switchgear is esssential for fault isolation, controlling power flow, and facilitating safe operation on transmission and distribution networks. With the development of the grid toward decentralized generation, increased loads, and digital automation, there has been a strong demand for intelligent switchgear monitoring. Real-time, non-invasive monitoring of elements such as breakers, busbars, and cable terminations allows early partial discharge, gas leak, and contact degradation detection.

Switchgear monitoring enables predictive maintenance, minimizes downtime, and prolongs asset life by providing enhanced safety, continuity of operation, and long-term performance

Why Rugged Monitoring

Reliable operation of switchgear is vital for ensuring the stability and safety of electrical power systems. As switchgear ages, its performance is impacted by electrical, mechanical, and thermal stresses, which contribute to insulation deterioration, busbar joint degradation, and circuit breaker contact wear. Early-stage problems such as partial discharge (PD) along the operating busbar, high contact resistance, and mechanical fatigue act as critical indicators of insulation breakdown and require timely detection to prevent complete switchgear failure.

Rugged monitoring comprehensive solutions includes non-intrusive sensors with edge processing units for synchronized data acquisition and on-site analytics. Data is visualized through our Enterprise APM suite RM EYE, providing enhanced diagnostics, automatic alarms , and remote monitoring.Also, software displays the values in graphical or numerical form as per the requirement. Our system supports continuous and periodic monitoring for new or retrofit installations.Proactive switchgear monitoring helps identify these problems early, preventing failures and ensuring reliable system performance.

What We Monitor-

Reliablilly monitor trip/close coil condition, contact wear and active part temperatures.

Detect hottest spot before failures occur for proactive fault prevention.

Track busbar temperatures and insulation degradation for reliable power flow.

Real-time arc detection and fault localization for fast asset response and safety.

Measure critical asset equipment to detect early overheating and enable proactive maintenance.

Track gas leaks and density to ensure safe operation and environmental compliance.

Capture and analyze discharge activity in real time to reduce unplanned switchgear failures.

Types of Switchgear

Invest in Efficiency & Sustainability

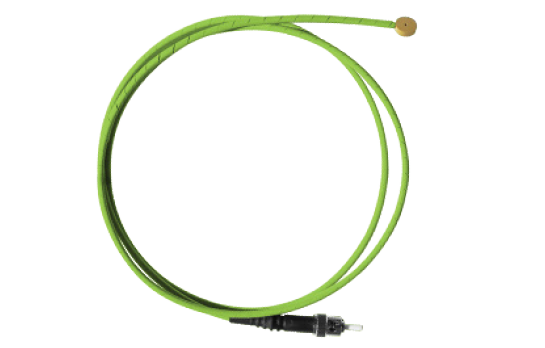

EMI-resistant fiber optic sensors for accurate monitoring of temperature, partial discharge, and contact resistance in switchgear.

Comprehensive, scalable, and precision-driven for acquiring synchronized data and supporting localized analytics across switchgear compartments.

Designed with intelligence to deliver AI-powered insights, real-time visualization, and enhance predictive switchgear health monitoring.

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.