Why Bus Bar Monitoring in Switchgear

As the demand for continuous switchgear performance increases, factors such as insulation breakdown, thermal stress, and environmental conditions like moisture and dust can lead to potential failures. Insulation degradation, causing partial discharges (PD), destabilizes the power system, disrupting its operational normalcy. Heat, stress, and vibration can create weak spots near the bus duct joints, indicating an early sign of asset deterioration. Additionally, busbar faults can create arc flashes, posing a major safety hazard.

Traditional maintenance of switchgear fails to capture these early signs of failure, resulting in long-term power outages and asset damage. With proactive condition monitoring of switchgear, these unreliability challenges are addressed in real time, ensuring low-cost maintenance, improved operations, and maximized asset efficiency.

Why Rugged Monitoring-

Rugged Monitoring’s switchgear bus bar monitoring solutions include intelligent IoT sensors, edge devices, and software that deliver real-time data on critical parameters such as partial discharge and temperature fluctuations. Our solutions are resilient in extreme operating environments with immune-to-interference sensing technology. They are scalable to meet the increasing demand for switchgear conditions and can be retrofitted to existing or new systems. Our solutions monitor and predict even the most minor fluctuations in insulation and temperatures, ensuring a consistent and efficient power supply.

With advanced analytics for various health and performance indices, our comprehensive system creates individual KPIs that can be customized through real-time alerts and interactive dashboards. By analyzing trends and other operating data remotely, our solutions empower predictive maintenance needs, minimizing operational costs and extending asset lifespan.

Invest in Efficiency & Sustainability

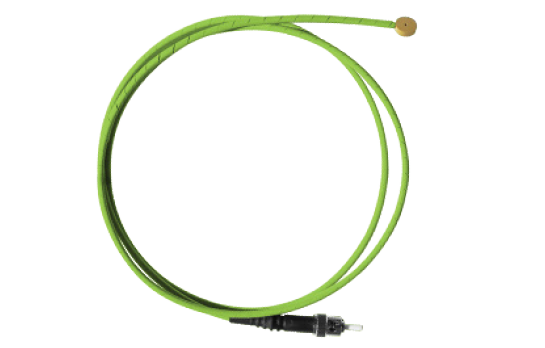

EMI-immune fiber optic sensors for real-time temperature rise and partial discharge detection along busbar systems.

Comprehensive and scalable edge devices for continuously monitoring busbar health and early detection of insulation or thermal anomalies.

AI-powered platform delivering predictive insights, custom alerts, and remote diagnostics for optimized busbar performance and reliability.

What We Monitor-

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.