Why Hotspot Monitoring in Switchgear

Hotspot detection on medium or high-voltage switchgear is a significant condition monitoring application because even minor overheating can drastically reduce insulation life and accelerate the risk of failure. Overheating is usually caused by loose connections or excessive current loads or degraded insulation leading to localized temperature rises referred to as hotspots on the primary circuit. Insulation near hotspots deteriorates rapidly due to thermal stress and becomes more susceptible to dielectric breakdown and internal arc faults.

Studies show that for every 10°C increase in the insulation temperature, its life will be reduced to half. This deterioration may lead to prolonged outages and expensive damage if not monitored. Real-time hotspot monitoring is essential to identify critical issues early and shift from periodic inspection to condition based maintenance.

Why Rugged Monitoring-

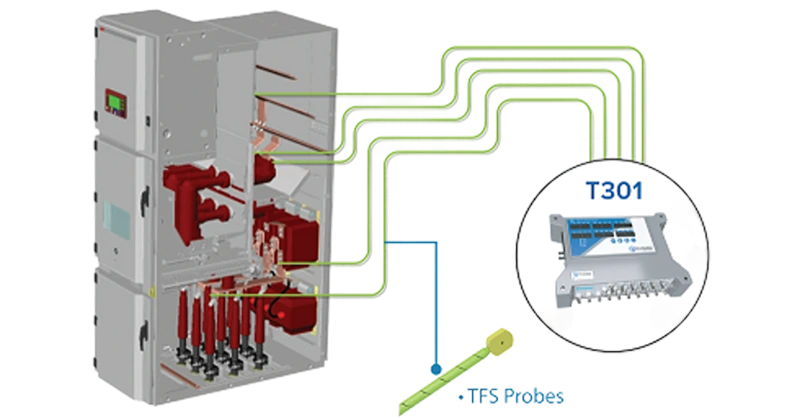

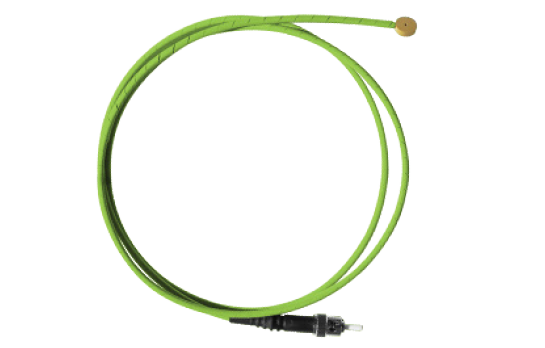

Rugged Monitoring’s Hotspot Monitoring System is a non-intrusive, real-time temperature monitoring system designed for Switchgear. our solutions are designed for harsh environments, inaccessible and hazardous locations, it uses fiber optic sensing technology to monitor thermal at critical components.Non-conductive and immune to electromagnetic interference, the sensors are mounted on parts like busbars, breaker contacts, and cable terminations which are areas susceptible to resistive heating.

By detecting thermal anomalies prior to failure, the system allows for predictive maintenance, minimizes the risk of unexpected outages, and avoids equipment damage. Combined with edge processing and analytics software, Rugged Monitoring delivers thermal profiling and hotspot localization capabilities that extend asset lifespan, increase system reliability, and increase safety in AIS, GIS, and MV switchgear applications.

Invest in Efficiency & Sustainability

Non-conductive, EMI-immune fiber optic sensors for real-time hotspot detection at breaker contacts, busbars, and cable terminations.

Comprehensive, scalable, and precision-driven edge devices for thermal profiling and localized hotspot tracking in harsh environments.

AI-powered platform providing predictive thermal insights, hotspot trend analysis, and advanced alerts to reduce failure risk and improve safety.

What We Monitor-

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.