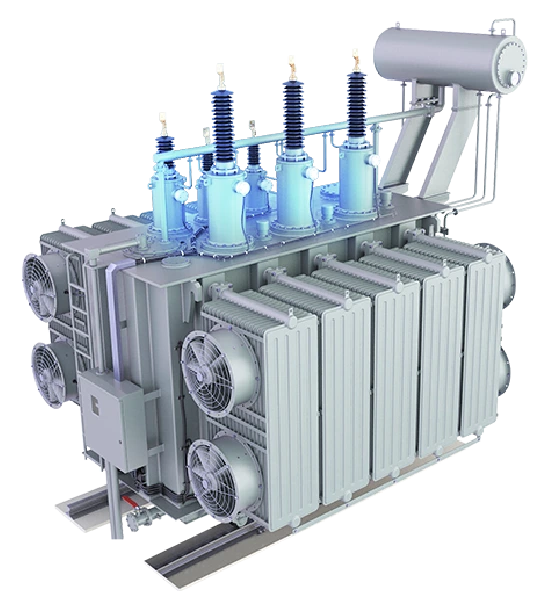

Why Bushing Monitoring in Transformer

Bushings are a major contributor to transformer failures resulting due to various stress factors such as intense electric fields, fluctuating thermal conditions, and exposure to other environmental contaminents. Overtime, these conditions can lead to insulation degradation compromising on transformer integrity and performance. Traditional bushing monitoring system typically emphasizes offline assessments of capacitance and power factor (tan delta), which are often conducted under static conditions, increasing asset downtime.

The advancements in bushing condition monitoring technologies have empowered organizations to adopt a more proactive approach that provides real-time insights into bushing health and performance. Thus, empowering businesses to maintain performance standards and minimize disruptions to grid stability.

Why Rugged Monitoring-

Rugged Monitoring’s comprehensive bushing monitoring in transformer utilizes advanced diagnostic techniques to effectively assess the health of bushing insulation. Our advanced IoT sensors, smart edge devices and software continuously monitor critical bushing parameters, including partial discharge and leakage current, without interrupting the normal operation of transformers.

Rather than depending on a single data point, our solutions adopt a holistic approach, evaluating multiple dimensions (electrical, thermal, and dielectric), to deliver a thorough analysis of bushing integrity. By localizing insulation defects such as voids and cracks, it ensures early fault detection of any anomalies.

Rugged Monitoring’s advanced bushing monitoring system transforms the way businesses understand and manage bushing health with real-time analysis that enhances the depth and accuracy of bushing monitoring.

Invest in Efficiency & Sustainability

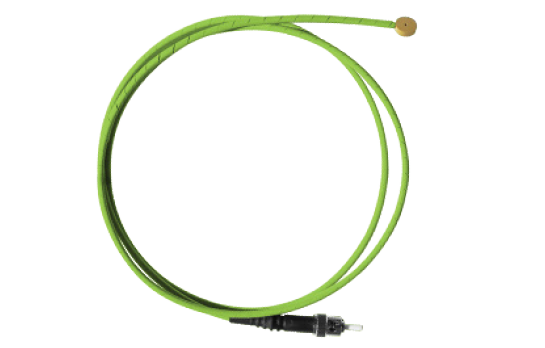

Measure capacitance, leakage current, and PD signals with our advanced bushing sensor.

Optimize bushing maintenance with accurate measurements of Tan δ and capacitance.

Monitor bushing challenges in real-time with customizable alarms and dashboards.

What We Monitor-

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.