Why Cooling Monitoring in Transformer

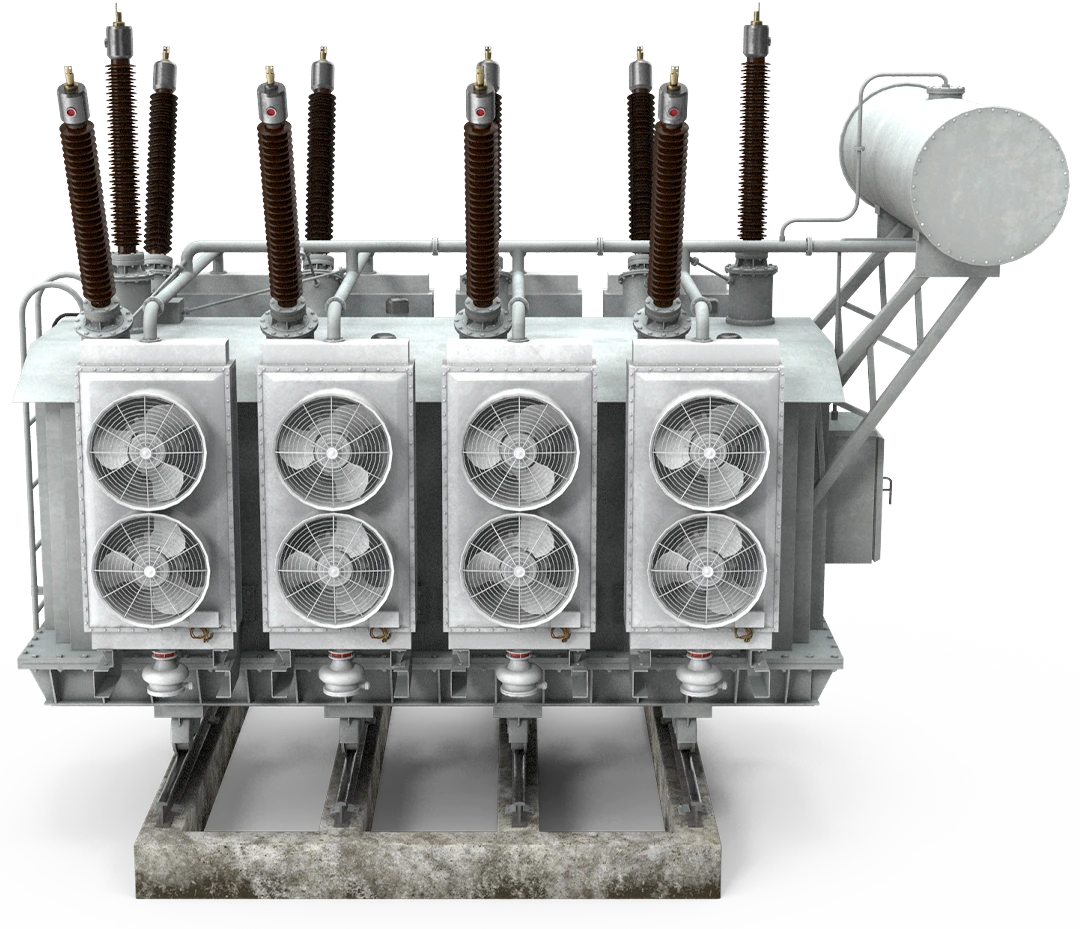

Transformers require cooling systems to manage the heat generated during operations, primarily due to electrical resistance and core losses. Adequate cooling is just not necessary to avoid overheating but also to ensure efficiency, prolonged lifespan and provide reliable transformer operations. The proper system has the capability to maximize transformer performance through air, oil, or advanced dielectric cooling techniques while minimizing energy losses and operating hazards.

Combining routine maintenance with real time monitoring to detect environmental factors, cooling systems function effectively and improve transformer longetivity.

Why Rugged Monitoring-

Cooling monitoring system is necessary to ensure that the transformer is running within safe thermal limits to improve performance, increase lifespan, and avoid unscheduled outages. Rugged Monitoring offers solutions for cooling performance that can be measured using our fiber optic temperature sensors. These solutions can also evaluate the efficiency of cooling system units such as fans and pumps. We also offer solutions that encompasses load conditions and environmental parameters such as ambient temperature and humidity. Automated alarm systems notify operators of any failures in the cooling system or of temperature deviations, allowing for timely action.

Real time and proactive monitoring of cooling performance prevents overheating, enhances operational efficiency, and supports to extend transformer lifespan.

Invest in Efficiency & Sustainability

What We Monitor-

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.