Why Hotspot Monitoring in Transformer

One of the critical parameters impacting transformer performance is hotspot temperatures. They directly influence the insulation capability of a transformer. Overtime, increase in temperature can lead to deploymerization of cellulose insulation, resulting in decreased tensile strength and elasticity. This process eventually renders the insulation brittle, comprimising its ability to endure long-term operational stress. Such irreversible degradation significantly reduces transformer lifespan, impacting its overall performance.

With real-time hotspot monitoring system, detection of even minor temperature fluctuations enable precise and timely intervention with proctive maintenance strategies. This continuous approach will empower businesses to mitigate maintenance costs and maximize ROI.

Why Rugged Monitoring-

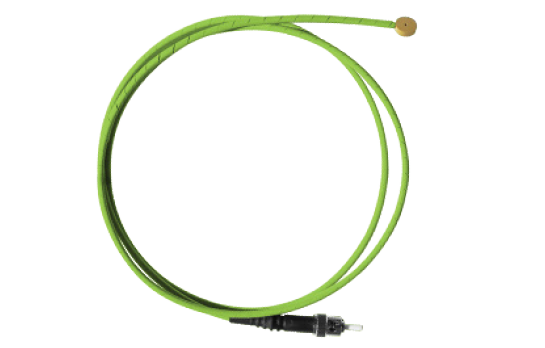

Rugged Monitoring’s hotspot temperature monitoring replaces manual diagnostics with a fully-automated, high-resolution solution. By utilizing fiber optic monitoring systems with IoT Sensors, Edge Devices and Software sensing technology, our solutions offer direct measurement of internal hotspot temperatures at critical points within transformer windings. Our highly-sensitive and immune to interference sensors can be either directly installed on transformer windings or retrofitted on new applications, ensuring reliability even in high-voltage environements without signal degradation.

This real-time data is processed locally using our smart edge devices, that analyze even minor thermal events, empowering operators and OEMs with data-driven insights into issues before they reach critical levels.

With Rugged Monitoring’s real-time monitoring system, businesses can now minimize risks and maximize uptime, aligning their proactive strategies with modern asset monitoring frameworks.

Invest in Efficiency & Sustainability

Advanced fiber optic sensors for early detection of localized hotspot anomalies.

Smart edge devices to ensure continuous monitoring of potential hotspot failures.

Streamline workflows and improve hotspot identification in real-time with RM EYE.

What We Monitor-

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.