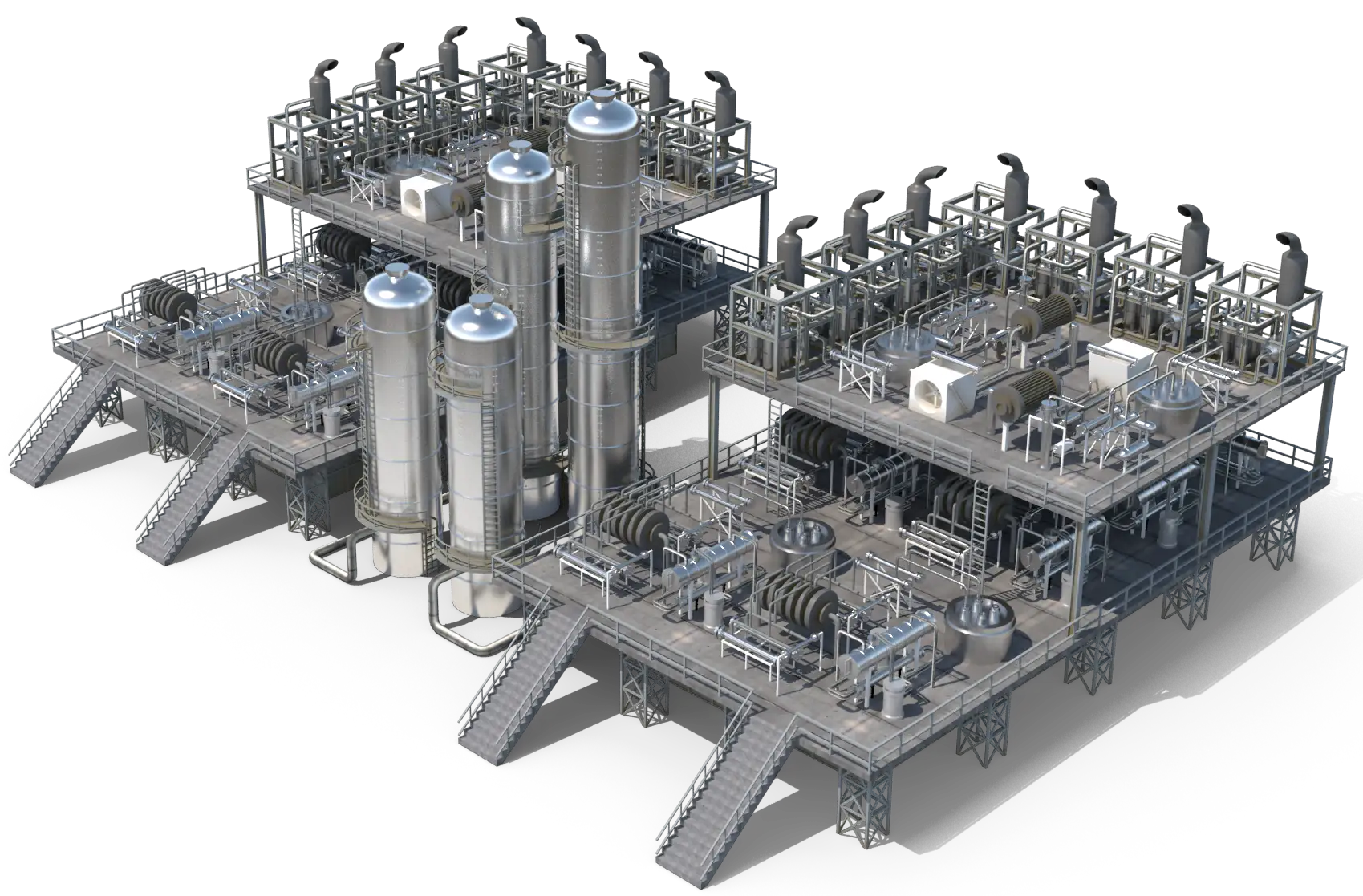

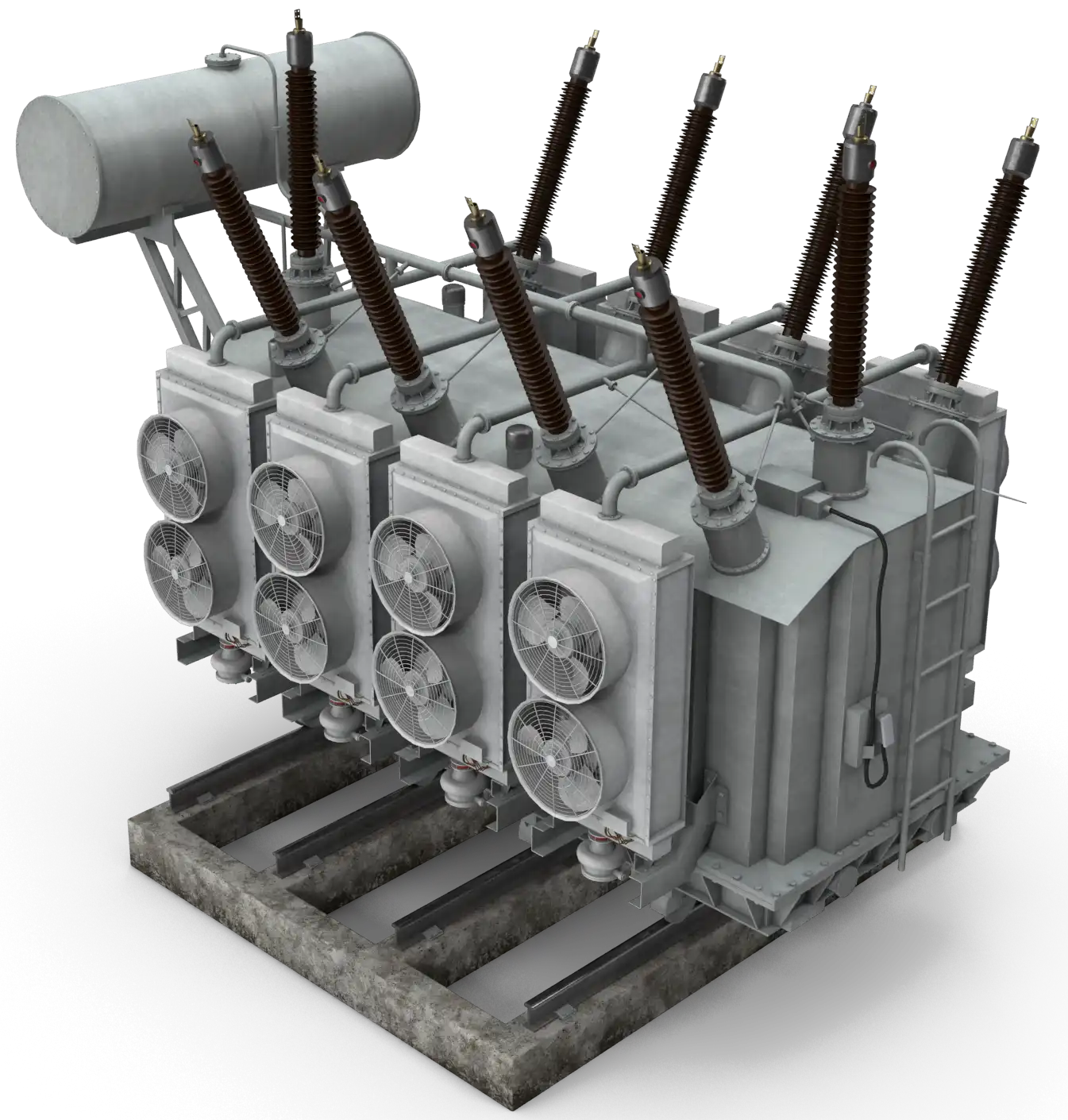

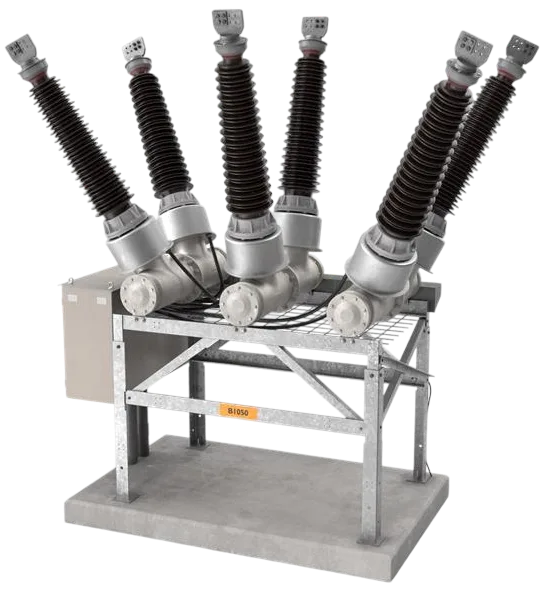

The oil & gas industry is one of the most energy-dependent sectors in the global supply chain. Spanning its operations across exploration, extraction, refining, transportation, and distribution, its infrastructure and profitability heavily rely on the operational efficiency of electrical assets. As it operates across diverse conditions, each segment of this industry presents unique electrical and operational demands.