Circuit Breaker Monitoring System

Why Circuit Breaker Monitoring System

Circuit breakers are the most essential electrical asset for any industry. Their goal is to reduce the risk of outages in a power system by interrupting the circuits when a fault or overload occurs. If the load exceeds a set capacity, it will cause the breaker to trip protecting the electrical network. Since they are used repeatedly, ensuring the asset is in perfect working condition is a necessity for the operational excellence of any electrical industry. Faults due to thermal overload, dielectirc discharges, insulation degradation, or gas leaks, can cause complete mechanical or electrical breakdown in circuit breakers.

Traditional maintenance practices, fall short in offering continuous monitoring that can preempt these failures before they occur. Whereas, proactive condition monitoring solutions identify critical faults in real-time, ensuring timely maintenance, while minimizing asset downtime and maintenance costs.

Why Rugged Monitoring

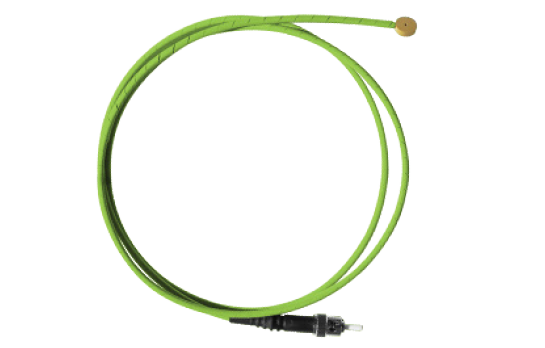

Rugged Monitoring’s advanced monitoring solutions are designed to address the critical challenges of a circuit breaker in tedious electrical systems. Our solutions address the critical risks within a cricuit breaker through high-precision IoT sensors, intelligent data acquisition edge devices, and software. By providing immunity to EMI, our sensors provide uncompromised real-time data even in harsh environments for temperature hotspots, bus bar, partial discharge, breaker condition, and SF6. By capturing and analyzing data in real-time, our comprehensive monitoring system provides early-stage indicators into catastrophic faults.

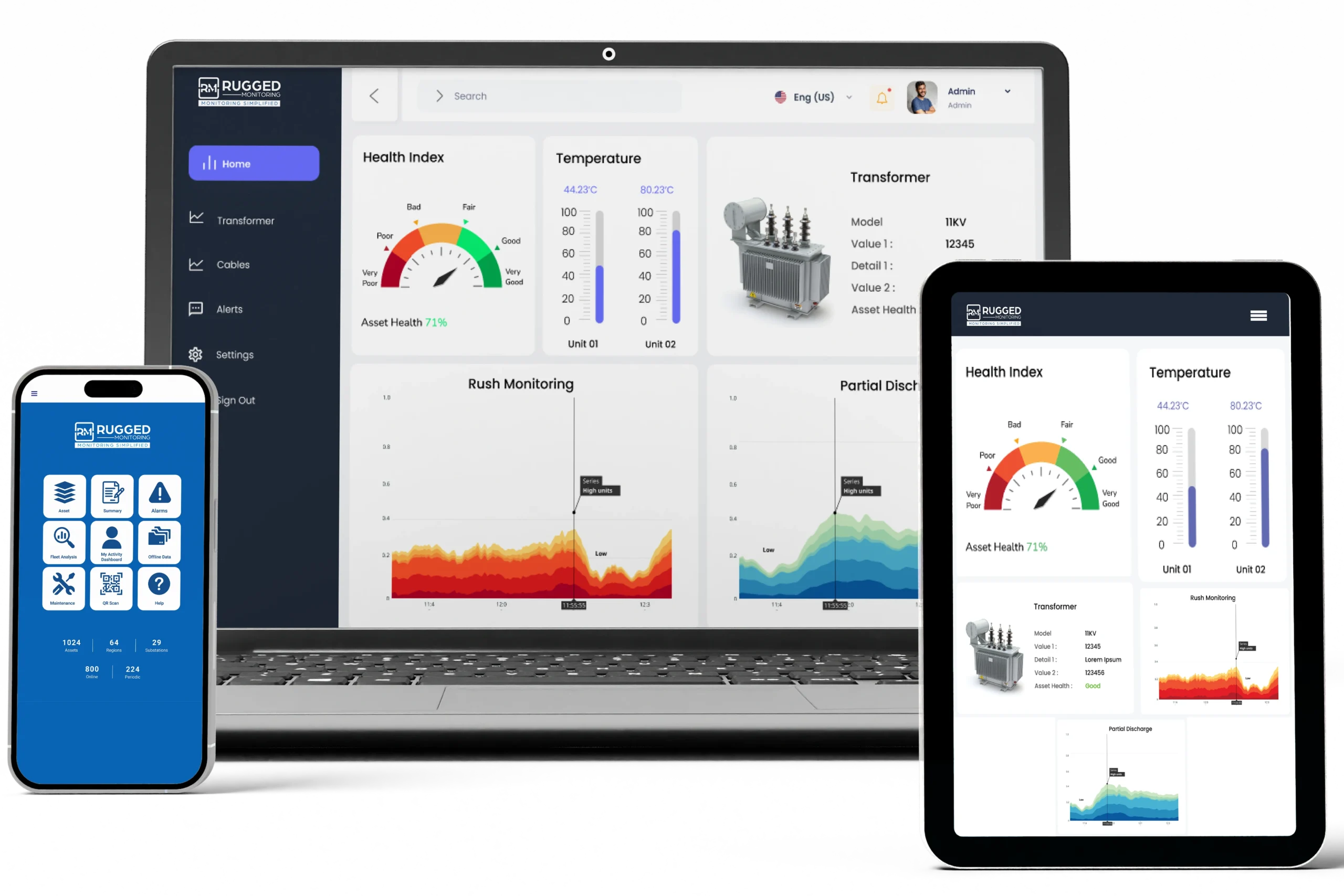

With options available for both retrofit and new installations, our solutions do not need recalibration and can be installed in busbars, contacts, or arc chambers, providing non-intrusive and highly stable inputs. By analyzing these inputs in a centralized software, our solutions provide data-driven insights, historical trend analysis, and predictive diagnostics that can be used to customize thresholds, alarms, and dashboards. Thus, empowering Asset Expert’s and Operational Engineers with a more resilient, cost effective maintenance strategy that improves switching relaibility, operational efficiency, and returns on investment.

What We Monitor-

What We Monitor-

Improve reliability and minimize downtime with real-time insights.

Detect hottest spot before failures occur for proactive fault prevention.

Real-time fault analysis of temperature and breaker position.

Continuous data-driven insights on breaker health and performance

Identify temperature fluctuations with our fiber optic technology.

Track SF6 gas density changes in real-time to ensure grid safety.

Types of Circuit Breaker

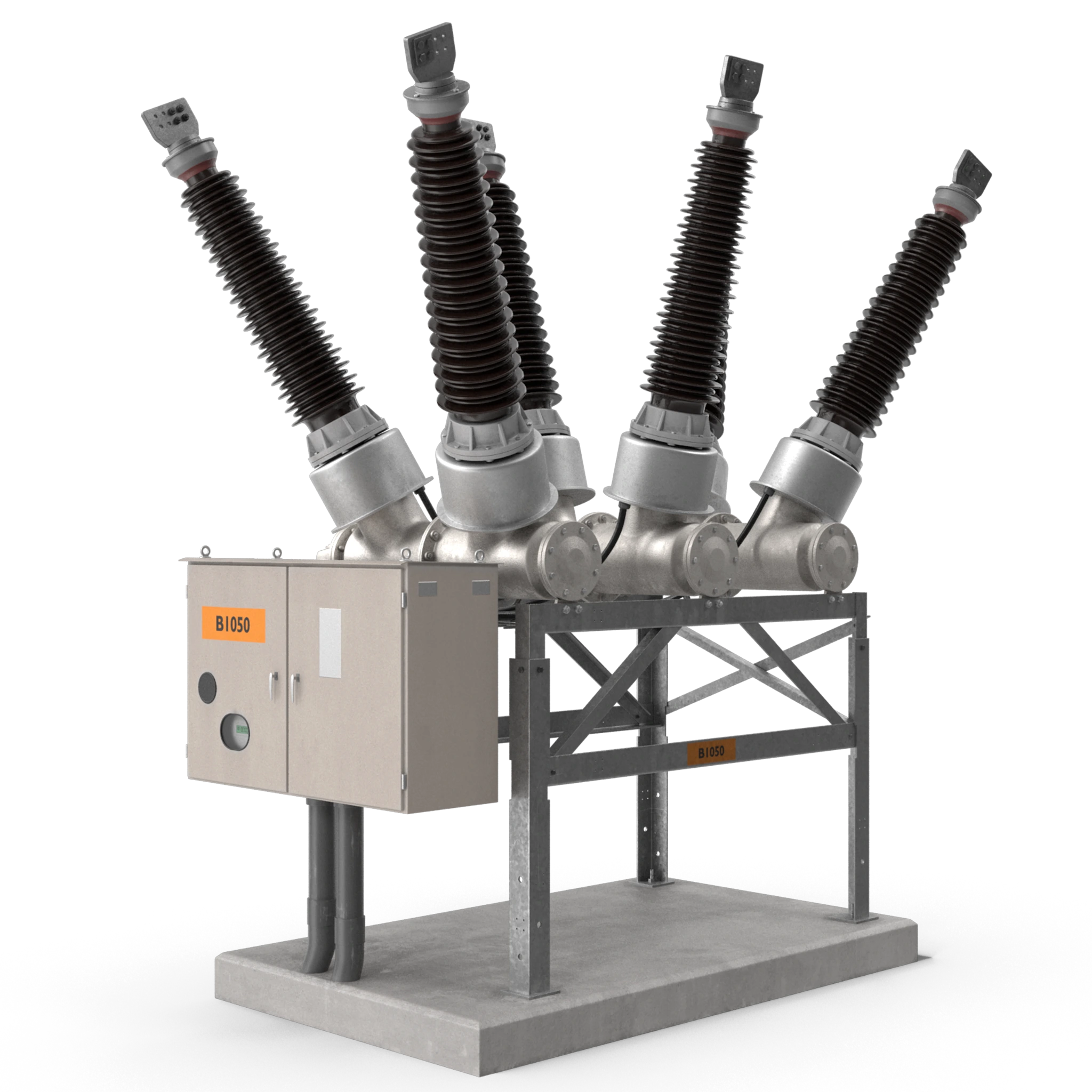

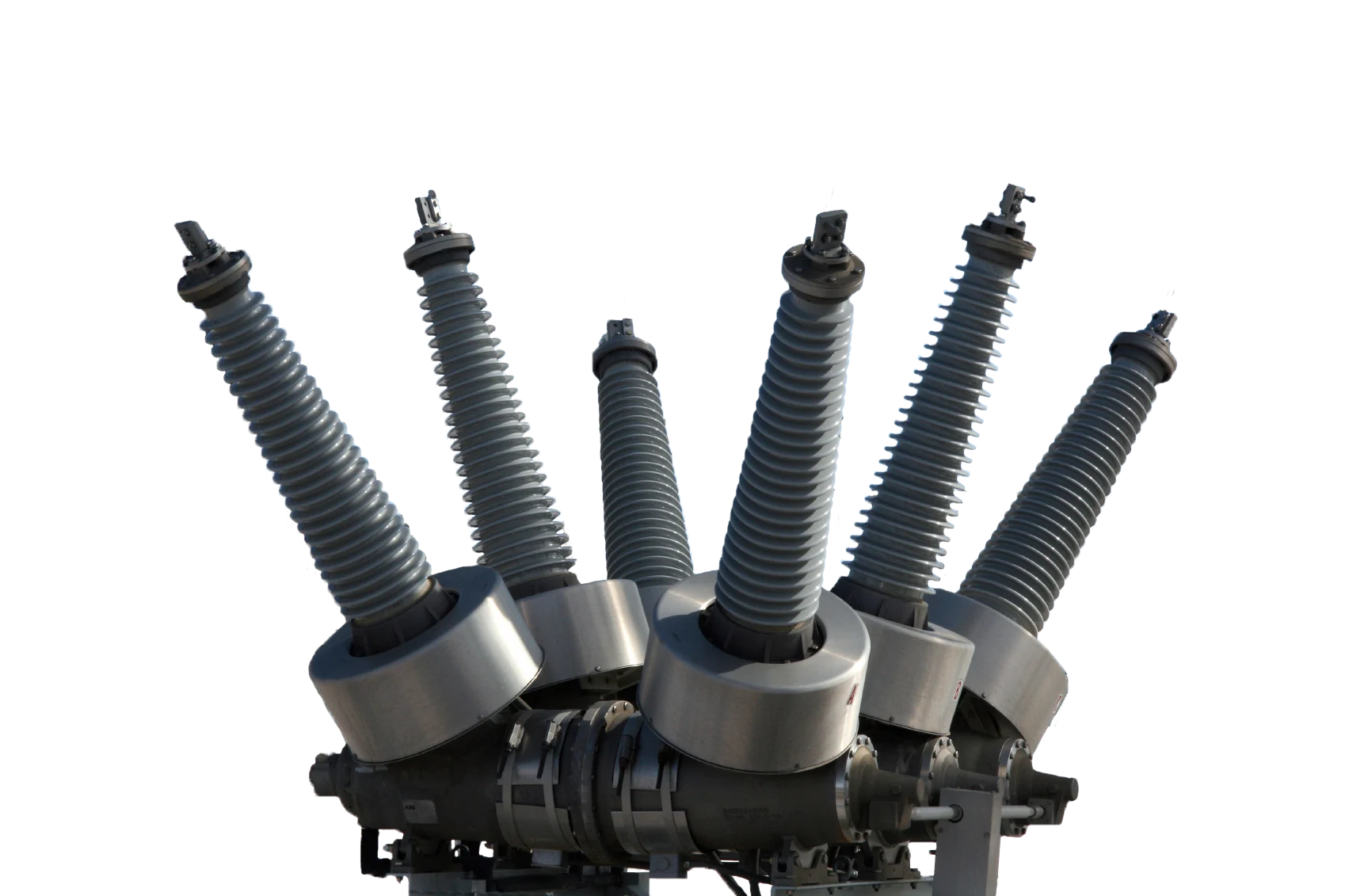

Improve Breaker Reliability and Enable Early Fault Detection with Our IPOB Monitoring System

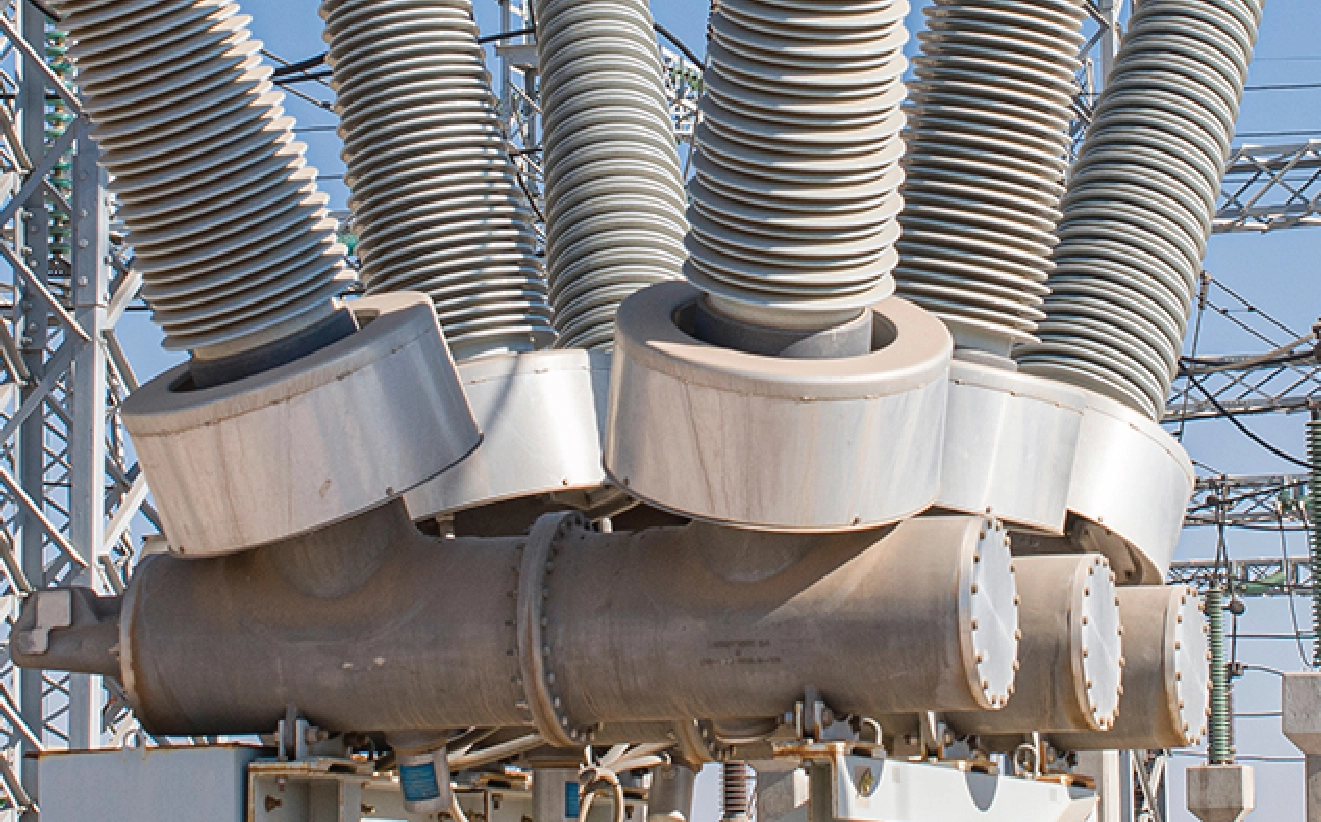

Ensure Synchronized and Optimized Performance with Our GOB Monitoring System

Extend Breaker Lifespan and Prevent Failures with Our Dead Tank Breaker Monitoring System

Invest in Efficiency & Sustainability

Resistant to electromagnetic interference enables highly accurate temperature monitoring, partial discharge, and SF₆ in harsh environments.

Comprehensive, scalable, and precision-driven for capturing real-time data across breaker contacts, busbars, and arc chambers.

Designed with intelligence to deliver AI-powered diagnostics and support predictive monitoring of circuit breaker health and performance.

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.