Rugged Monitoring's

Detect faults early, extend asset life, and maximize uptime with Rugged Monitoring’s intelligent transformer bushing solutions.

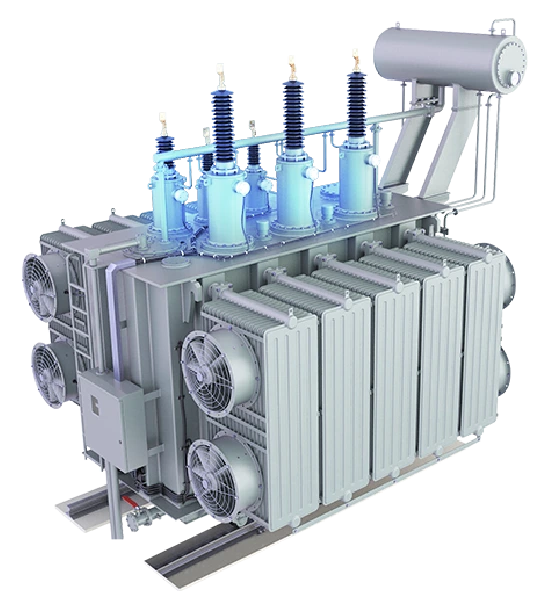

Power grids are complex networks comprising numerous electrical assets. Among them, transformers are placed at key points to adjust voltage levels and ensure electricity flows efficiently across the system. However, transformer reliability largely depends on critical components such as bushings. Each bushing insulates and supports the high-voltage conductor as it passes through the transformer tank, ensuring safe and reliable operation.

A transformer bushing is an insulated terminal that allows an electrical conductor to pass safely through the metallic tank or casing of a transformer. It acts as a barrier that prevents high voltage from leaking or discharging to grounded parts of the equipment, ensuring safe and efficient current flow.

Bushings are engineered to handle high voltages and currents while preventing dielectric breakdown between the conductor and the transformer casing. They create a secure and insulated pathway for electrical connections, protecting the transformer from electrical stress and insulation failure.

Transformer bushings are essential because they ensure electrical isolation, mechanical stability, and operational safety under high-voltage conditions. A single bushing failure can trigger cascading outages across the entire grid, posing a threat to critical infrastructure and public safety.

Here’s why bushings play such an irreplaceable role in transformer reliability:

Some designs allow voltage tapping for adaptable power delivery across the grid.

Bushing operates in challenging environments where they are exposed to surface contamination, electrical discharges, and other stresses. Even a small amount of moisture ingress can quickly deteriorate the insulation, leading to potential failure. Such failures not only compromise the transformer’s performance but also cause severe equipment damage and costly downtime. This emphasizes the importance of regular bushing monitoring and maintenance.

Continuous monitoring of electrical parameters provides a proactive approach to assessing the condition of transformer bushings. By tracking key indicators, such as capacitance, power factor, tan delta, and partial discharge activity, it becomes easier to detect deviations or unusual patterns early. This enables timely corrective actions, helping prevent major failures that could impact operational efficiency and safety.

The result?

The sum of current method monitors transformer bushings by measuring the total leakage current that flows through all bushings together.

In this approach, an initial sum of current reference is first established using data from the bushing nameplate or results from off-line testing. New measurements are then compared with this baseline to identify any variations in capacitance and tan delta, which indicate changes in insulation condition. Advanced proprietary algorithms are often applied to refine the analysis and ensure reliable detection of even minor deviations.

Key advantages:

Rugged Monitoring strengthens this method with intelligent features for improved accuracy, enhanced visibility, and increased reliability.

Our solution goes beyond tracking total leakage current. It also captures key parameters such as capacitance and tan delta (dielectric dissipation factor), delivering a complete and more accurate picture of bushing condition.

Rugged Monitoring’s advanced bushing monitoring system builds upon this proven method to address traditional limitations and enhance overall transformer monitoring performance.

In fact, this approach has already demonstrated measurable success in real-world applications. For instance, at the North Hyde Substation, it played a crucial role in improving transformer reliability and minimizing unplanned outages, clearly highlighting how data-driven monitoring directly supports operational continuity.

The system is designed for flexibility and scalability, offering a cost-effective and easy-to-integrate solution. It retains the strengths of fundamental techniques while adding advanced features and analytics to improve overall transformer health.

It also integrates seamlessly with multi-site and multi-asset APM platforms such as RM EYE. This integration enables a unified view of transformer condition and long-term reliability across all connected assets and locations.

The BSENS is a sensor designed for real-time evaluation of transformer bushings. By analyzing key parameters such as leakage current, capacitance, and tan δ, it provides predictive diagnostics. The system is compatible with condensing or capacitive-type bushings, as well as transformer and breaker bushings. BSENS also features a wide frequency range of 100kHz to 25 MHz, ensuring highly precise detection of PD signals. It offers several advantages, including early fault detection, easy installation, accurate data acquisition, and flexible configurations tailored to specific application needs

The BM201 is an advanced standalone monitoring solution built to provide real-time insights for up to six bushings operating in high-voltage substation conditions. It provides real-time diagnostics, early fault detection, and flexible bushing tap connections suitable for different bushing types. The module ensures accurate measurement of tan δ and capacitance, includes dual protection in the event of an earthing link failure, and offers simple installation with compatibility across multiple monitoring technologies.

The R501 is a versatile transformer monitoring solution equipped with an integrated bushing monitoring module. Designed for adaptability, it supports a wide range of functions, including temperature monitoring, partial discharge detection, OLTC (On-Load Tap Changer) supervision, cooling system evaluation, and relay output management. This all-in-one system provides a comprehensive view of transformer health, ensuring maximum reliability and uptime across critical electrical assets.

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.