The importance of fiber optic temperature sensors for temperature monitoring cannot be overstated. The demand for reliable assets is enabling most businesses to invest in solutions with real-time monitoring. Although traditional solutions, such as WTIs, RTDs, or thermocouples, provide a temporary fix, they are not capable of preventing failures before they occur.

In this blog, we will explore what fiber optic sensors are and how they can be used in the proactive monitoring of electrical assets.

What are Fiber Optic Temperature Sensors?

Fiber optic temperature sensors employed in electrical asset monitoring utilize light as their primary transmission medium. Instead of the electrical conductors commonly used in traditional methods, they rely on a light signal sent through their optical fiber medium to the sensing tip. This tip features a special material, such as fluorescent material, which emits light when excited. Depending on the temperature at the fiber optic sensor tip, the time it takes for the light to fade varies, known as the decay time. This decay time is measured to know the exact temperature of that critical asset component. By utilizing such fundamental properties of light, fiber optic sensors ensure external faults are identified with high sensitivity and accuracy.

Fiber optic sensors can be of two types:

- Intrinsic: Instead of using an external tip as the sensing material, this type of fiber optic temperature sensor uses its optical fiber to determine the light phase changes. Temperature directly interacts with the fiber, causing changes within. This change is then measured to determine the magnitude of temperature fluctuations. A common type of intrinsic sensor is the Fiber Bragg Grating (FBG) sensor.

- Extrinsic: These fiber optic temperature sensors are most commonly used for temperature monitoring of electrical assets. Instead of modulating the light inside the fiber like intrinsic fiber optic sensors, extrinsic sensors modulate the light signal outside the fiber. A key characteristic is their immunity to electromagnetic interference, ensuring efficiency and reliability even in extreme conditions.

Types of Fiber Optic Sensing Technologies used in Condition Monitoring

- Gallium Arsenide (GaAs): The fiber optic sensor tips are designed using gallium arsenide crystals. Instead of relying on decay time, GaAs sensing technology utilizes bandgap properties for temperature measurement. They are commonly used in demanding applications, such as the aerospace and defense industries, due to their small sensing tip size.

- Fluorescence: Fluorescence-based fiber optic temperature sensors calculate temperature deviations based on decay time. With high-dielectric properties even in harsh environments, they are best suited for applications that require no calibration, like power industries or oil & gas.

How are Fiber Optic Temperature Sensors used in Condition Monitoring?

Fiber optic temperature sensors can be perfectly tailored for electrical asset condition monitoring. They are non-conductive, robust, and intrinsically safe, ensuring distributed sensing over long distances. Additionally, with immunity in extreme environments, high accuracy, and continuous monitoring, they provide long-term durability and reliability. When combined with edge devices and asset performance management systems, fiber optic sensors offer real-time data-driven insights to enable predictive maintenance.

But here’s how fiber optic sensors justify their investment:

- Wide temperature range: By ensuring accurate measurements in both extremely high and low temperatures, they offer adaptability and durability in extreme environments. This is especially useful in energy-intensive industries like oil and gas, refineries, or OEMs.

- Easy installation without recalibration: Fiber optic temperature sensors are fairly easy to install with minimal ongoing maintenance. With some sensors, durability lasting 100+ years without the need for recalibration, optical temperature sensors provide the highest ROI compared to traditional sensors.

- Minimal risk of human error: As fiber optic sensors respond and adjust to the shift in transmission properties in real-time, the accuracy of temperature readings is maximized. Thus, it reduces the probability of false readings that occur with manual inspections or traditional monitoring.

- Enhanced adaptability: Fiber optic temperature sensors are engineered to be lightweight and compact in size. This makes it easier to install in tight spaces or retrofit existing applications. Thus, increasing their potential to adapt to critical industries such as aerospace or automotive applications.

- Distributed temperature sensing: Also known as DTS sensing, is the ability of fiber optic sensors to measure along their entire length. This ensures multi-point sensing, making it a cost-effective solution, especially for large industrial processes.

Thus, optical temperature sensors aid in the predictive maintenance of electrical assets by detecting even the most minor temperature changes with precision and reliability.

Fiber Optic Temperature Sensors for Predictive Maintenance

When integrated with APM systems using edge devices, any fiber optic sensor ensures more reliable and actionable data for predictive maintenance.

Fiber Optic Temperature Sensors– They act as the first layer of predictive maintenance architecture installed at critical points of any electrical asset. They continuously monitor real-time temperature faults of the asset and communicate the signals to edge devices.

Fiber Optic Edge Devices – Using the same technologies as fiber optic sensors, such as GaAs or Fluorescence, these edge devices convert the optical signal into digital signals. Using advanced communication protocols such as Modbus or RTU, these signals are ingested into advanced APM software, where the analysis takes place.

Asset Performance Management System – APM systems utilize AI/ML algorithms to analyze and provide data-driven, actionable insights into temperature conditions. These insights can be used to customize thresholds & alarms, analyze trends, monitor KPI’s, and predict faults before they occur.

Applications of Fiber Optic Sensors in Electrical Asset Monitoring

As a comprehensive solution with monitors and APM, industries can ensure an efficient thermal analysis of their electrical assets.

- Transformer Condition Monitoring– Fiber optic temperature sensors for power transformers ensure the real-time monitoring of winding hotspots. This ensures that heavy-duty industries or utilities minimize downtime and maximize asset availability.

- Switchgear Condition Monitoring: Fiber optic sensors for switchgear installed at critical points such as breaker contacts, busbars, and cable joints. This continuously detects early signs of temperature failures, enabling proactive maintenance.

- Rotating Machine Condition Monitoring: Fiber optic temperature sensors for rotating machines identify potential issues such as overheating in real-time, maximizing asset performance and efficiency.

- Circuit Breaker Condition Monitoring: By using advanced optical temperature sensors, companies can preempt faults with early warning signs and maximize breaker reliability.

- Cable Condition Monitoring: Businesses can prevent asset failures and minimize safety risks using fiber optic temperature sensors for power cables.

How to Choose the Right Fiber Optic Temperature Sensor?

- For higher sensitivity, low initial costs, and industrial monitoring purposes- GaAs fiber optic temperature sensors.

- Medical

- Semiconductor

- Cryogenics & Research Labs

- Aerospace

- Defense

- For faster response times, no recalibration, higher accuracy, and extreme conditions- Fluorescence-based fiber optic sensors

- Oil and gas

- Refinery

- Energy sector

- OEMs

- Renewables

Rugged Monitoring’s Fiber Optic Monitoring Solutions

Rugged Monitoring offers a complete fiber optic condition monitoring system. Our solutions consist of fiber optic temperature sensors, edge devices, and enterprise APM, RM EYE. With the empowerment of both GaAs and fluorescence-based sensing, our solutions are easy to install, highly accurate, and offer real-time insights for predictive maintenance.

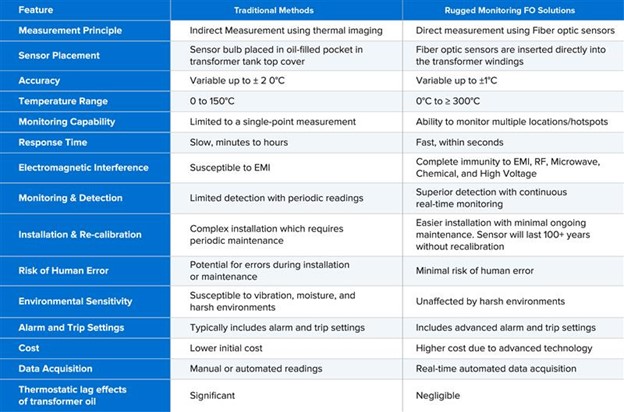

Our fiber optic sensors are highly advantageous compared to traditional methods:

With a modular approach to condition monitoring, the benefits of our comprehensive fiber optic system include:

- Minimized asset downtime

- Optimized Maintenance

- Enhanced Safety

- Data-Driven Insights

- Accurate & Robust Design

- No recalibration

For industries looking to shift from reactive to proactive condition monitoring, contact our sales team today!