Why Gas Insulated Switchgear (GIS) Monitoring

Gas-insulated switchgear plays a vital role in compact, high-voltage power systems. Issues such as SF₆ gas leakage, contact degradation, breaker delays, and internal partial discharge can compromise system integrity and safety.

The continuous,real time condition monitoring, trending, and diagnostics of GIS components helps to detect developing issues early, improve system availability, lower maintenance costs, and provide environmental compliance. Accurate gas density monitoring and partial discharge measurement are essential for ensuring equipment condition and avoiding failure at high expense.

Why Rugged Monitoring-

Gas-insulated switchgear (GIS) is a metal-enclosed system filled with an insulating gas, such as sulphur hexafluoride (SF6), with outstanding dielectric strength. The gas insulates and extinguishes any arcs that could develop during the switching operations.

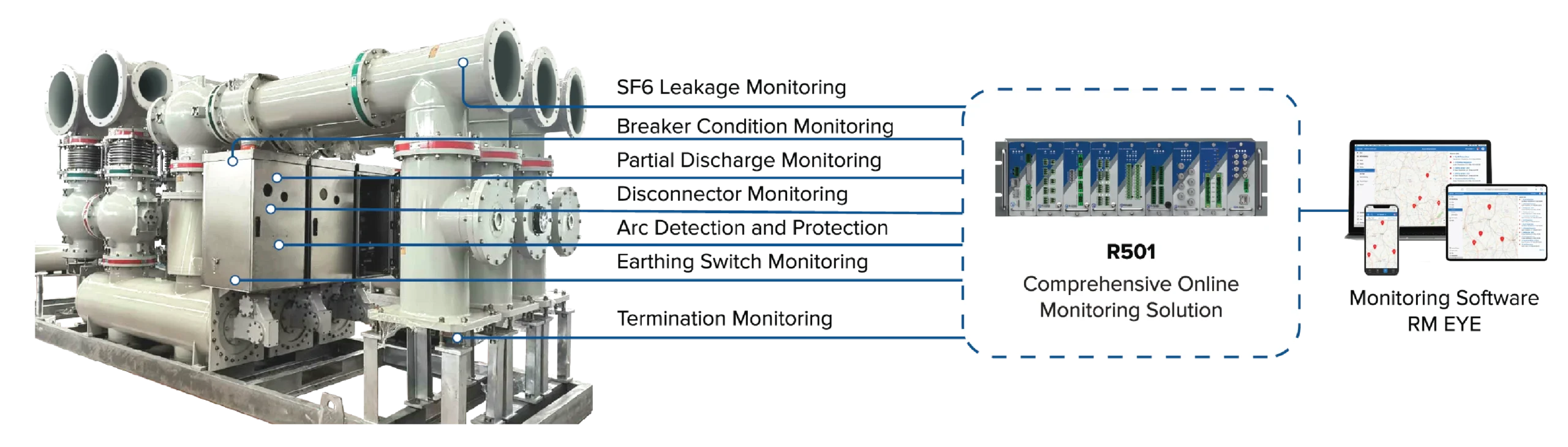

However, degradation or leakage of SF₆ may compromise the insulation’s performance and system safety. Rugged Monitoring offers a comprehensive condition monitoring solution that tracks parameters in real-time, including SF₆ gas density, temperature, partial discharge activity, trip/close timing, breaker condition, and arc events. Utilizing IoT sensors, Edge devices, and software that support centralized monitoring of multiple switchgear systems, provide bay-level information with quick and flexible configuration options, and an accurate alarm and alert system, increasing asset life with reduced unplanned outages.

We customize our GIS condition monitoring solutions based on specific application requirements. Seamless integration is available for both new and retrofit switchgear installations.

What We Monitor-

What We Monitor-

Measure critical asset equipment to detect early overheating and enable proactive maintenance.

Reliablilly monitor trip/close coil condition, contact wear and active part temperatures.

Detect hottest spot before failures occur for proactive fault prevention.

Real-time arc detection and fault localization for fast asset response and safety.

Track gas leaks and density to ensure safe operation and environmental compliance.

Capture and analyze discharge activity in real time to reduce unplanned switchgear failures.

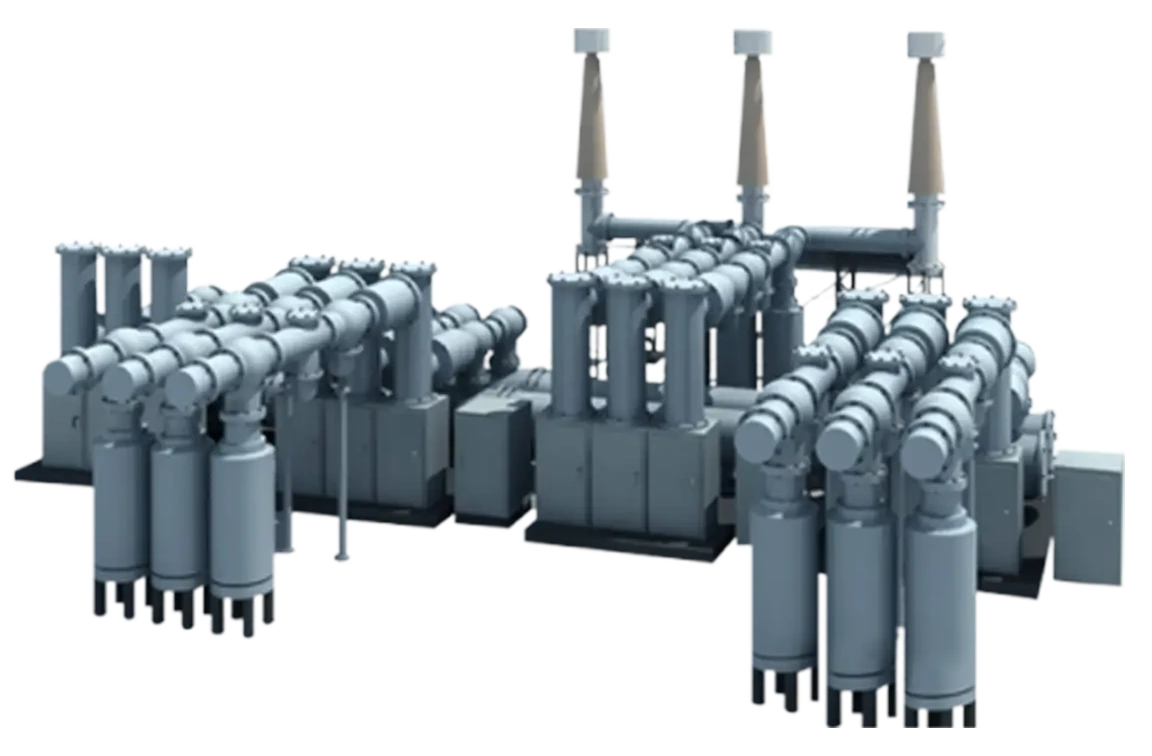

Types of Switchgear

Invest in Efficiency & Sustainability

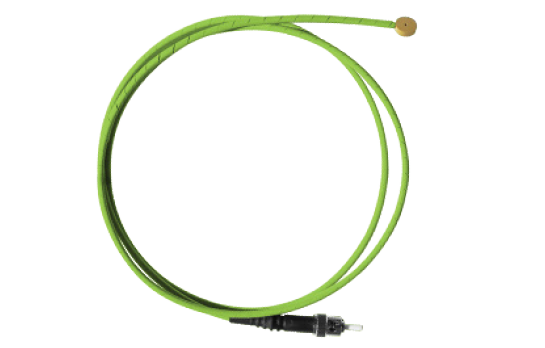

EMI-resistant fiber optic and gas sensors for accurate monitoring of SF₆ density, temperature, and partial discharge in GIS.

Scalable and high-precision devices for real-time acquisition of GIS parameters, supporting bay-level diagnostics and local analytics.

AI-powered platform for centralized GIS monitoring, delivering predictive insights and alarm alerts across switchgear systems.

Have questions or need more information? Reach out to us for reliable Rugged Monitoring solutions.