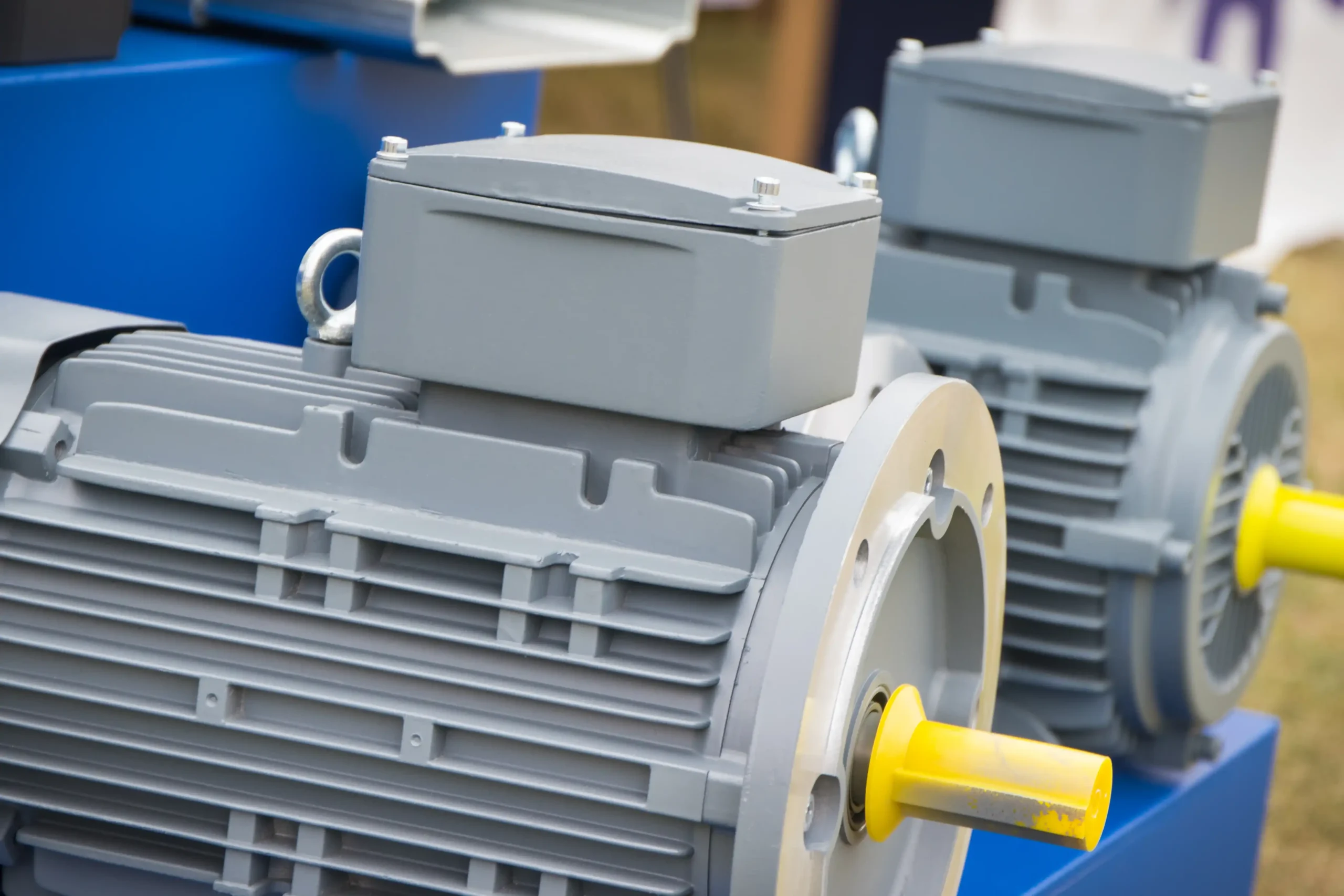

Why Cooling Monitoring in Rotating Machines

Cooling in rotating machines such as motos and generators is directly responsible for the thermal stability of the asset. As these machines continuously work under high-load, they generate substantial amount of heat due to electrical losses in core, bearings, and windings causing overheating, winding failures, and insulation degradation. These faults quickly escalate resulting in unplanned downtime, expensive maintenance, and complete shutdown of the operational network. With unplanned maintenance, transient or cumulative issues are often neglected resulting in increased operational risks and safety.

On the contray, proactive maintenance monitors and identifies these issues in real-time allowing condition-based intervention for anomalies such as leaks, pump failures, and fouling. For industries that heavily rely on rotating machines, continuous insights into their asset’s performance and health translates to lower cost of fault ownership, optimized efficiency, and improved asset reliability.

Why Rugged Monitoring-

Rugged Monitoring’s fiber optic solutions including IoT sensors, edge devices, and software ensure direct, real-time measurement of internal thermal conditions. Unlike traditional solutions, our sensors are directly embedded into critical locations such as stator windings, rotor cores, and bearings where typical sensors cannot function reliably and where overheating is most likely to occur. Our sensors are immune to electromagnetic inteferences and offer high spatial accuracy in real-time. With a millisecond-level responsiveness, our solutions track thermal variations even in the most dynamic conditions.

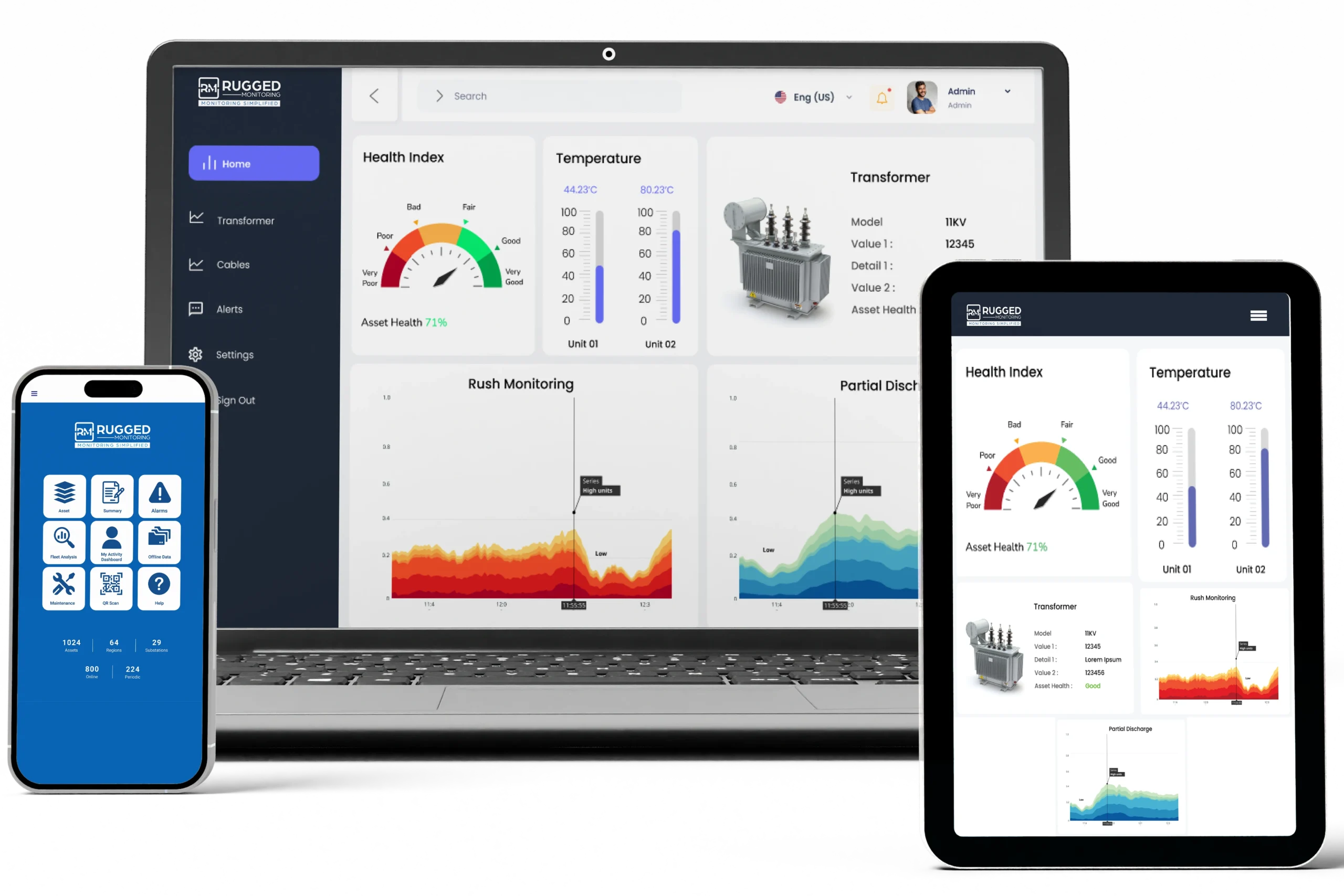

By identifying cooling efficiencies such as partial blockages or uneven heat dissipation, our solutions enable early fault detection long before they manifest into major mechanical or electrical failures. Allowing real-time data processing, Rugged Monitoring’s cooling monitoring system for rotating machines, offers customizable alarms and thresholds, allowing maintenance teams to take targeted, data-driven actions. By offering non-intrusive installation, high-precision sensing, and intelligent analytics, our solutions support businesses with reliabiliy-centered maintenance and maximized ROI.

Invest in Efficiency & Sustainability

EMI-resistant sensors deliver high-resolution data from critical zones, enabling reliable detection of thermal issues in harsh environments.

Scalable and precise, enabling real-time thermal analysis and early identification of abnormal heat patterns.

AI-powered platform providing thermal insights, anomaly detection, and predictive maintenance.

What We Monitor-