Why Hotspot Monitoring in Rotating Machines

The continuous electromagnetic energy conversion creates a large number of thermal high points in rotating machines. These hotspots dissipate extreme heat over a prolonged period of time, leading to catastrophic failures. Such high temperatures can be caused due to high-speed, alternating flux, insufficient cooling, and insulation degradation. Traditional maintenance methods are inefficient in detecting these issues before they occur. They often rely on techniques that increase asset downtime and cost of maintenance.

But with proactive maintenance, hotpots can be identified in real-time. Online condition monitoring solutions also, allows remote accessibility of hotspot occurrences enhancing safety and interventions. With such advanced improvements in predictive maintenance, asset managers are empowered with improved operational efficiency and highest ROI.

Why Rugged Monitoring-

Rugged Monitoring’s intelligent IoT sensors, edge-devices, and software for Hotspot Monitoring in rotating machines is a complete solution that proactively addresses potential issues before they escalate into major incidents. Our advanced fiber optic sensing technology localizes complex stress factors causing temperature hotspots at multiple points. They are compact, flexible, and immune to electromagnetic interferences, making them suitable for extreme operating conditions. Along with a quick response time and a standard deviation of +/-0.2 °C, our solutions do not need recalibration and can be installed on new or retrofit equipment.

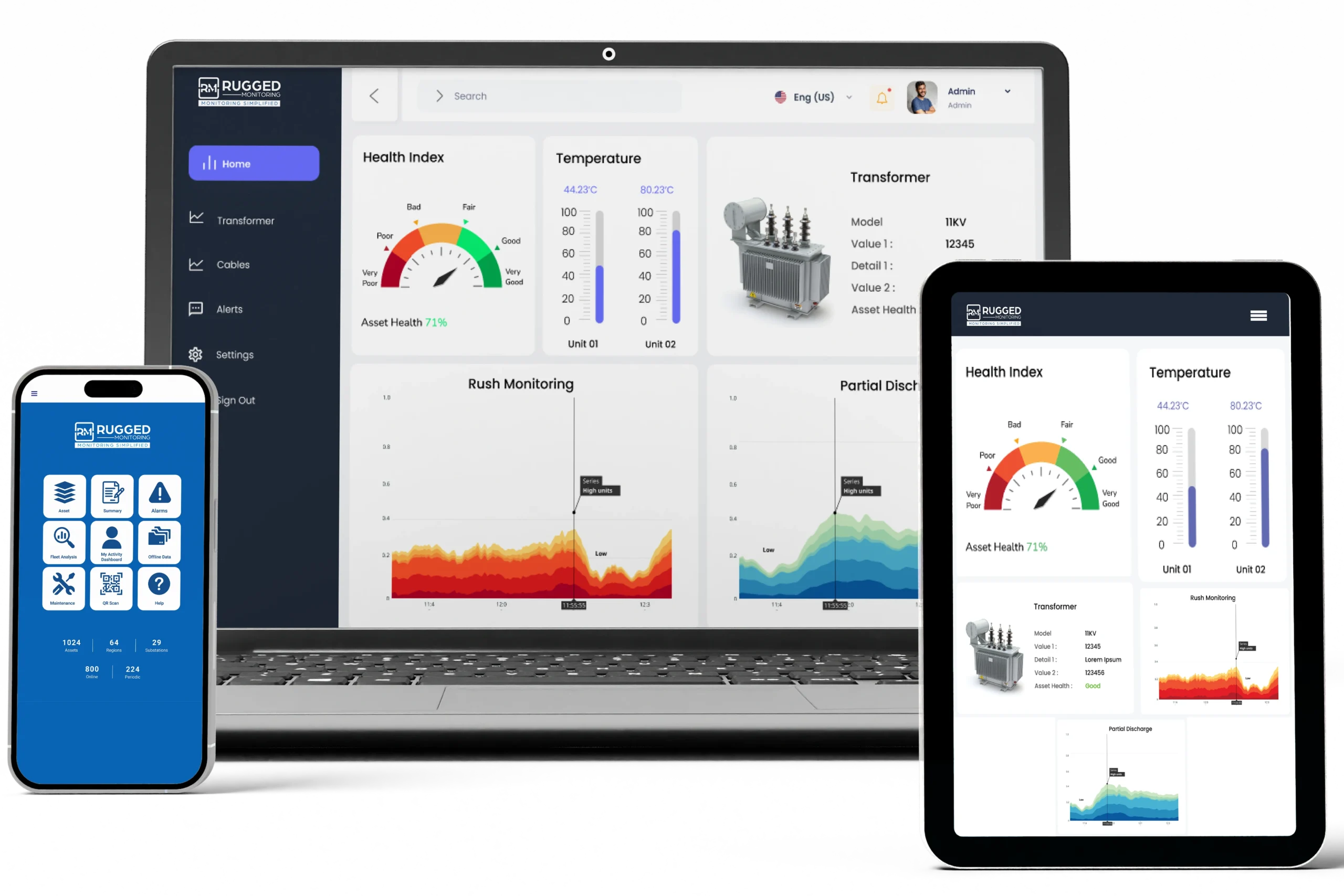

Our comprehensive hotspot monitoring system combines remote capabilities with robust datalogging and analytics for precise real-time results. Additionally, advanced features such as customizable dashboards and alerts empower subject matter experts with unparalleled visibility to identify anomalies, assess temperature levels, and prioritize actions. Our solutions not only strongly emphasize reliability but also minimize asset downtime and cost of maintenance.

Invest in Efficiency & Sustainability

EMI-immune fiber optic sensors with fast response and high accuracy, enabling real-time detection of temperature hotspots in extreme environments.

Scalable and high-precision, supporting localized data processing and trend analysis for early identification of thermal anomalies.

AI-powered platform offering real-time hotspot tracking, customizable alerts, and predictive insights to reduce downtime and maintenance costs.

What We Monitor-